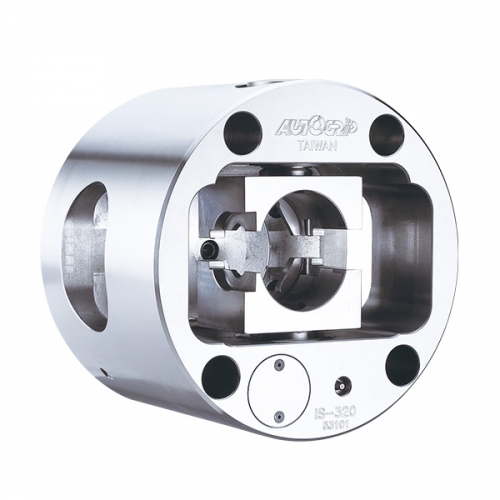

IS

| Model | Index Angle Deg | Jaw stroke (mm) | Chucking Area Dia. Max.(mm) | Chucking Area Dia. Max.(mm) | Max. pressure MPa (kgf/cm2) | Max. clamping force kN (kgf) | Max. speed min-1 (r.p.m.) | I kg‧m 2 | Weight (kg) | ROTATING JOINT | Main Spindle Bore(mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| IS-254 | 4x90゜ | 20 | 65 | 160 | 45 | 19.5 (1990) |

1700 | 0.41 | 41.0 | IS-315 | 70 and above |

| IS-275 | 4x90゜ | 20 | 80 | 220 | 45 | 25.4 (2590) |

1500 | 0.61 | 52.0 | IS-315 | 70 and above |

| IS-315 | 4x90゜ | 20 | 100 | 230 | 45 | 25.0 (2550) |

1200 | 1.13 | 76.0 | IS-315 | 70 and above |

* Index Angle 8x45° or Specific Angle, Please contact AUTOGRIP for more detailed information.Thanks.

* Subject to technical changes.

| Model | A | B | B1 | B2 | C(H6) | D | E | F | G | H | J | K | L | M | N | N1 | P | Q(H7) | R | S(H7) | T | U | V | W |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IS-254 | 254 | 190 | 5 | 23 | 220 | 171.4 | 60 | 13 | 47.5 | 18 | 155 | 48 | 13 | M8 | 20 | 5 | 40 | 18 | M10 | 20 | 106 | 57 | 46.5 | 5.5 |

| IS-275 | 275 | 213 | 5 | 26 | 220 | 171.4 | 60 | 13 | 58 | 20 | 171 | 48 | 18 | M10 | 20 | 6 | 80 | 18 | M10 | 20 | 125 | 67 | 57 | 7 |

| IS-315 | 315 | 232 | 5 | 22 | 220 | 171.4 | 60 | 13 | 71 | 18.5 | 187 | 50 | 18 | M10 | 20 | 6 | 75 | 24 | M12 | 25 | 125 | 85 | 70 | 7.5 |

.jpg)