Production Equipment

Production Equipment

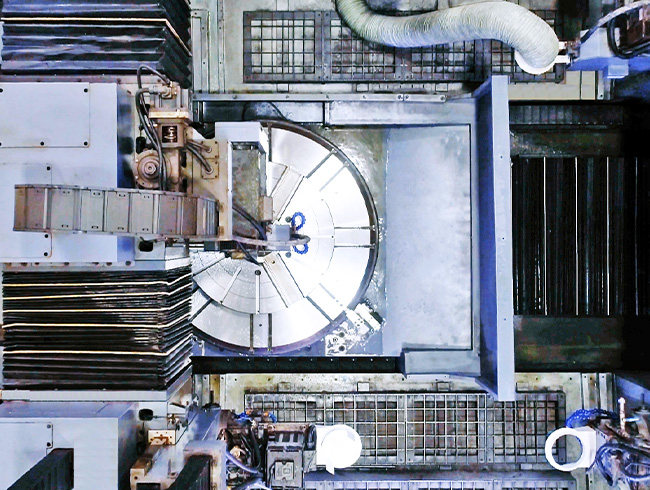

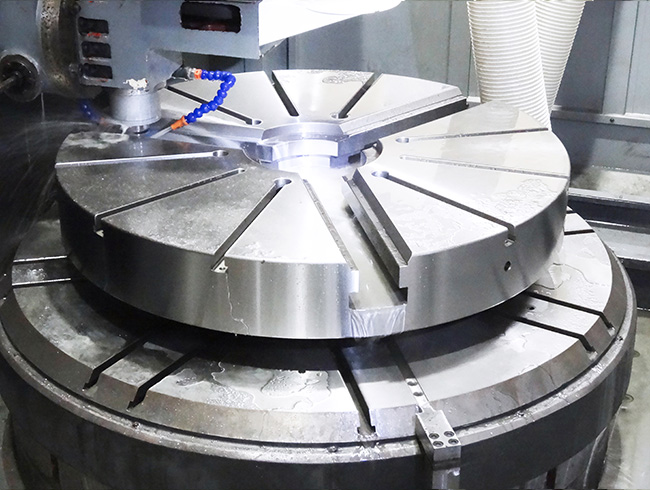

>> Turning and Machining

AUTOGRIP possesses horizontal machining centers for mass production, and advanced turn-mill centers and five-axis machining centers for high-mix low-volume production. With the equipment mentioned above, we are able to pursue flexible and efficient production mindset.

>> Grinding

Air purification and air-conditioned system are installed in the grinding plant not only for improving the accuracy of products and production efficiency but also for employees’ health.

Chuck body, wedge plunger, and master jaws can be ground by a wide variety of grinding equipment developed by ourselves, achieving fast and high accuracy manufacturing process. Also, we have a column grinding machine, which is capable of grinding for large work pieces.

>> Assembly

Every assembly staff have undergone strict training to implement self-inspection onto standard operation procedure by in-line inspection equipment and tools.

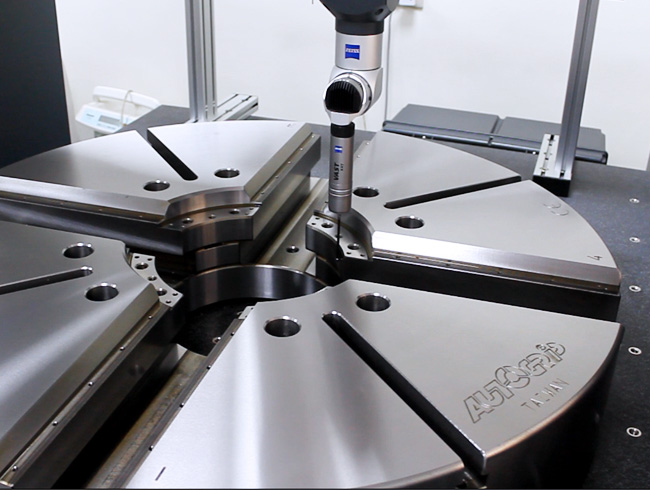

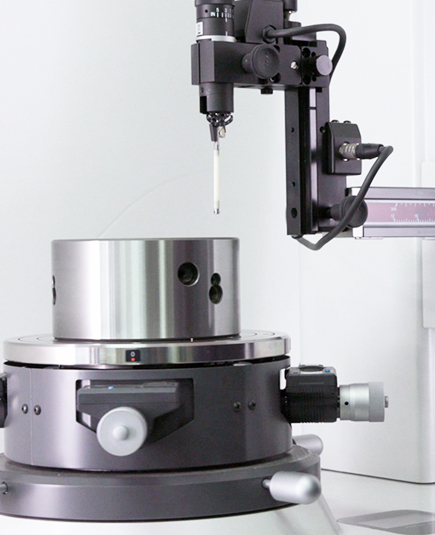

>> Quality Assurance

AUTOGRIP is ISO 9001:2015 certified and possesses multiple inspection equipment, such as coordinate measuring machine, roundness tester, profilometer, height gauge, hardness tester and so on. Additionally, our ISO/IEC 17025 certified mechanical testing lab keeps a closed eye on the quality of machine tool chucks and parts.

>> Warehouse

To ensure accurate inventory and safe stock, we introduce WMS (Warehouse Management System), utilizing QR Code to optimize storage process.