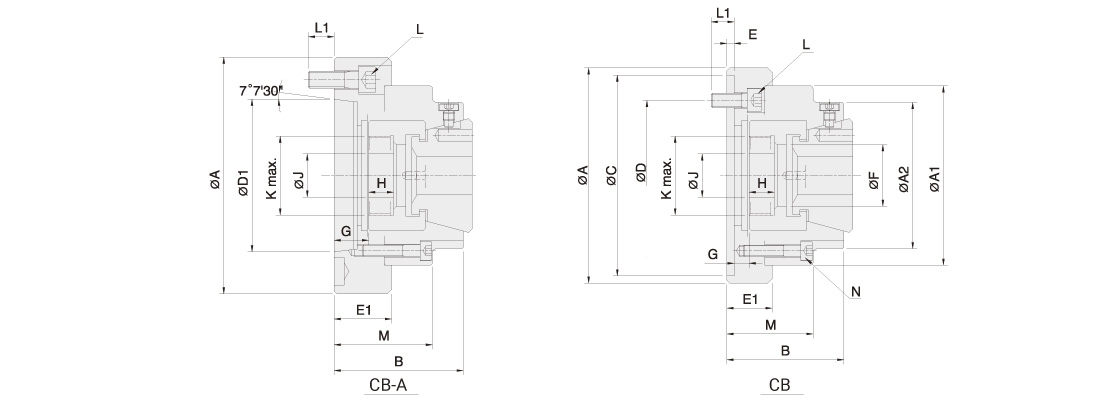

CB/CB-A

| Model | - | Plunger stroke(mm) | Max. Chucking Capacity Round (mm) | Max. Chucking Capacity Hexagom (mm) | Max. Chucking Capacity Square (mm) | Max. D.B. pull kN (kgf) | Max. clamping force kN(kgf) | Max. speed min-1(r.p.m.) | Weight (kg) | Matching Stell Collet | Matching cyl. | Max. pressure (kgf/cm2) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CB-42 | - | 4.5 | 4~42 | 7~36 | 7~30 | 34.3(3500) | 78.4(8000) | 7000 | 6.5 | RG-42 | TK-B846 | 2.8(28) |

| CB-42 | A5 | 4.5 | 4~42 | 7~36 | 7~30 | 34.3(3500) | 78.4(8000) | 7000 | 6.2 | RG-42 | TK-B846 | 2.8(28) |

| CB-42 | A6 | 4.5 | 4~42 | 7~36 | 7~30 | 34.3(3500) | 78.4(8000) | 7000 | 7.4 | RG-42 | TK-B846 | 2.8(28) |

| CB-52 | - | 4.5 | 4~52 | 7~36 | 7~45 | 39.2(4000) | 92.1(9400) | 7000 | 6 | RG-52 | TK-A853 | 3.2(32) |

| CB-5217 | - | 4.5 | 4~52 | 7~36 | 7~45 | 39.2(4000) | 92.1(9400) | 7000 | 9.6 | RG-52 | TK-A853 | 3.2(32) |

| CB-52 | A5 | 4.5 | 4~52 | 7~36 | 7~45 | 39.2(4000) | 92.1(9400) | 7000 | 6.5 | RG-52 | TK-A853 | 3.2(32) |

| CB-52 | A6 | 4.5 | 4~52 | 7~36 | 7~45 | 39.2(4000) | 92.1(9400) | 7000 | 7.8 | RG-52 | TK-A853 | 3.2(32) |

| CB-65 | - | 4.5 | 4~65 | 8~56 | 8~46 | 44.1(4500) | 103(10500) | 5500 | 15 | RG-65 | TS-866 | 3.0(30) |

| CB-65 | A6 | 4.5 | 4~65 | 8~56 | 8~46 | 44.1(4500) | 103(10500) | 5500 | 13.6 | RG-65 | TS-866 | 3.0(30) |

| CB-65 | A8 | 4.5 | 4~65 | 8~56 | 8~46 | 44.1(4500) | 103(10500) | 5500 | 17.6 | RG-65 | TS-866 | 3.0(30) |

| CB-80 | - | 4.5 | 5~80 | 8~68 | 8~56 | 50.0(5100) | 115(11730) | 5500 | 19 | RG-80 | TK-A1287 | 2.3(23) |

| CB-80 | A8 | 4.5 | 5~80 | 8~68 | 8~56 | 50.0(5100) | 115(11730) | 5500 | 19 | RG-80 | TK-A1287 | 2.3(23) |

* Subject to technical changes.

| Model | - | A | A1 | A2 | B | C(H6) | D | D1 | E | E1 | F | G max. | G min. | H | J | K max. | L | L1 | M | N |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CB-42 | - | 150 | 125 | 102 | 81.5 | 140 | 104.8 | - | 5 | 31 | 43 | 10.5 | 6 | 17.5 | 30 | M55x2 | 3~M10x25 | 11 | 60 | 4~M8 |

| CB-42 | A5 | 140 | 125 | 102 | 91.5 | - | 104.8 | 82.56 | - | 41.5 | 43 | 25.5 | 21 | 17.5 | 30 | M55x2 | 4~M10x25 | 12 | 70 | 4~M8 |

| CB-42 | A6 | 165 | 125 | 102 | 91.5 | - | 133.4 | 106.38 | - | 45 | 43 | 29 | 24.5 | 17.5 | 30 | M55x2 | 4~M12x35 | 18 | 73.5 | 4~M8 |

| CB-52 | - | 150 | 125 | 102 | 83.5 | 140 | 104.8 | - | 5 | 31.5 | 53 | 11 | 6.5 | 17.5 | 30 | M60x2 | 4~M10x25 | 16 | 62.5 | 4~M8 |

| CB-5217 | - | 180 | 125 | 102 | 87 | 170 | 133.4 | - | 5 | 35 | 53 | 14.5 | 10 | 17.5 | 30 | M60x2 | 4~M12x30 | 18 | 66 | 4~M8 |

| CB-52 | A5 | 140 | 125 | 102 | 93.5 | - | 104.8 | 82.56 | - | 41.5 | 53 | 26 | 21.5 | 17.5 | 30 | M60x2 | 4~M10x30 | 16 | 72.5 | 4~M8 |

| CB-52 | A6 | 165 | 125 | 102 | 99 | - | 133.4 | 106.38 | - | 47 | 53 | 31.5 | 27 | 17.5 | 30 | M60x2 | 6~M12x35 | 18 | 78 | 4~M8 |

| CB-65 | - | 185 | 145 | 120 | 100 | 170 | 133.4 | - | 6 | 50 | 66 | 13.5 | 9 | 21.5 | 32 | M75x2 | 6~M12x40 | 20 | 73.5 | 4~M8 |

| CB-65 | A6 | 165 | 145 | 120 | 111 | - | 133.4 | 106.38 | - | 61 | 66 | 30.5 | 26 | 21.5 | 32 | M75x2 | 4~M12x40 | 20 | 84.5 | 4~M8 |

| CB-65 | A8 | 207 | 145 | 120 | 107 | - | 171.4 | 139.72 | - | 57 | 66 | 26.5 | 22 | 21.5 | 32 | M75x2 | 4~M16x40 | 24 | 80.5 | 4~M8 |

| CB-80 | - | 235 | 175 | 150 | 112 | 220 | 171.4 | - | 5 | 37 | 82.5 | 13.5 | 8 | 25 | 45 | M85x2 | 6~M16x30 | 22 | 87 | 6~M10 |

| CB-80 | A8 | 210 | 175 | 150 | 125 | - | 171.4 | 139.72 | - | 50 | 82.5 | 26.5 | 21 | 25 | 45 | M85x2 | 6~M16x50 | 24 | 100 | 6~M10 |

.jpg)