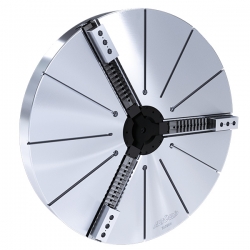

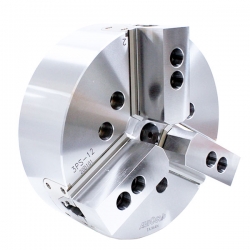

Power Chucks

Autogrip® is a well-known brand power chuck manufacturer in Taiwan. Since 1989, we have worked with numerous machine builders around the world. Our power chucks category features various types such as thru-hole, non-thru-hole, large-thru-hole, long jaw stroke, and vertical lathe power chucks, providing our customers with exceptional flexibility and adaptability. We also offer jaw chucks with different configurations ranging from 1, 2, 3, 4, and 6 jaws power chucks, professionally customized and made to order for your lathe power chucks service. The V series power chucks can handle workpieces up to 2,000mm (79”) in diameter.

Our power chucks offer high rigidity, infallible precision, and stability, allowing our customers to increase efficiency and productivity while being cost-effective. Our R&D department is committed to continuously improving our products to meet the high demands of our global customers. Contact Autogrip® today to learn more about how Autogrip can help enhance your manufacturing operations.

The Types and Versatility of Autogrip® Power Chucks:

Autogrip® power chuck has the following features and advantages:

Features:

- The power chuck is a rigid coupling that can transmit power under high torque and high speed.

- The power chuck uses a clamping device to clamp the workpiece, which allows for quick installation and replacement of the workpiece.

- The clamping force of the power chuck can be controlled by adjusting the clamping force to adapt to different machining workpieces.

Advantages:

- The power chuck has high torque transmission and rigidity, which ensures the stability and accuracy of the workpiece at high speeds.

- Due to the even distribution of clamping force on the workpiece, the power chuck can achieve high-precision machining and higher processing efficiency.

- The power chuck can adapt to different workpiece shapes and sizes, making it applicable in a wide range of industries.

Autogrip® power chucks can be applied in the following areas:

- Metalworking industry: Power chucks are typically used on lathes, milling machines, drilling machines, and grinding machines to clamp and transmit power and torque to workpieces.

- Robotics: Power chucks can be used at joints in robots to achieve high-precision and high-torque movements.

- Precision machining: Power chucks can be used to machine high-precision components such as optical components, electronic components, and precision mechanical parts.