Solving the Clamping Challenge for Irregular Workpiece Machining

Our project addresses the challenge of clamping irregular-shaped workpieces, which cannot be effectively positioned using traditional 3 jaw or 4 jaw chucks. Since the core task is precision boring of the inner diameter, achieving accurate centering is critical: misalignment leads to eccentric cutting and dimensional errors, severely impacting machining accuracy and stability.

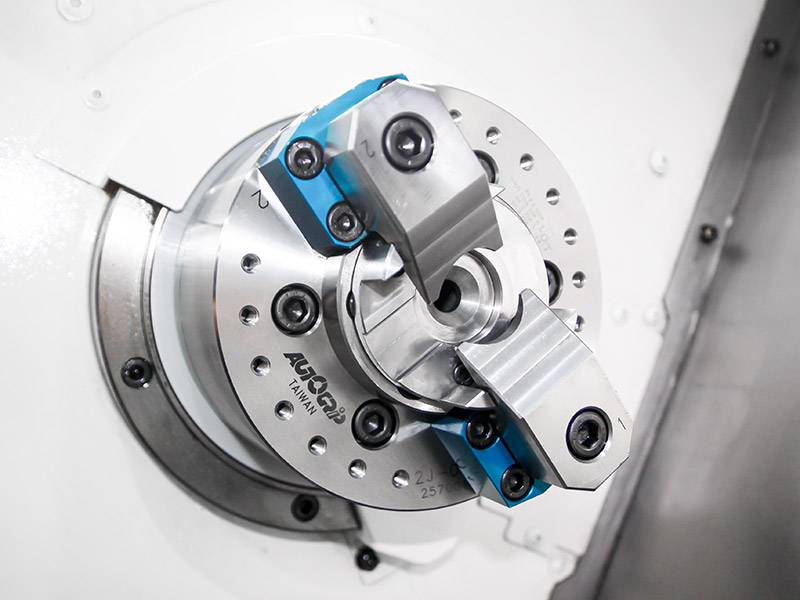

To overcome this, we adopted a Finger Power Chuck (2J) with a compensating jaw mechanism. Originally designed with a rotational down press motion for vertical positioning and clamping, the chuck’s rotation could interfere with the auxiliary centering fixture.

Therefore, we reconfigured the jaw actuation sequence: centering is first accomplished by the auxiliary fixture, after which the Finger Power Chuck(2J) performs vertical clamping. This ensures precise centering and significantly improves turning stability and machining quality.

Custom-Designed

Jaws and Support Plate for a Perfect Fit

Supporting this application, we developed custom jaws and a matching support plate to conform precisely with the workpiece’s end face and locating holes. This ensures instant centering at the moment of clamping, while preventing lateral slipping or lift during machining—thereby enhancing clamping rigidity and operational safety.

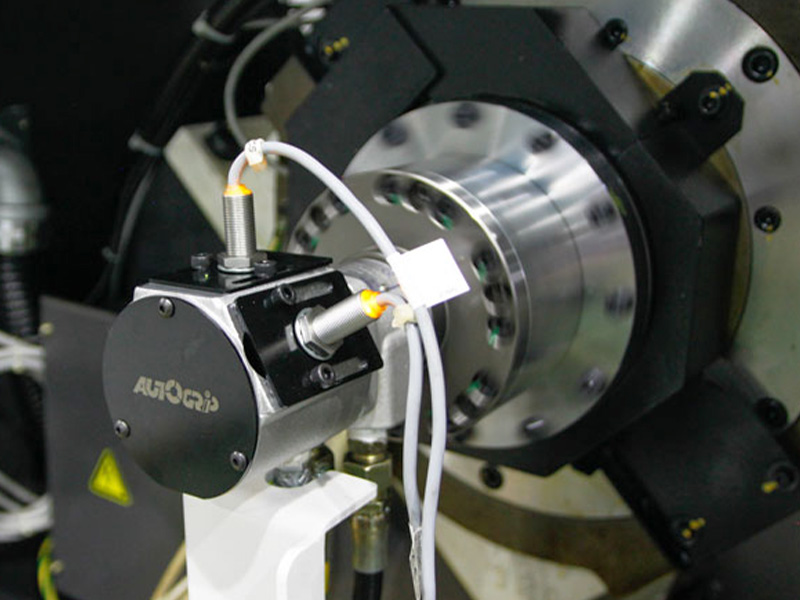

High-Performance Drive: Short Type Rotary Hydraulic Cylinder with Stroke Control and Safety Device(RS type)

The system integrates the RS Short Type Rotary Hydraulic Cylinder with Stroke Control and Safety Device (Non Thru Hole), offering the following features:

• Compact, high-speed, and stroke-controlled design—ideal for environments with space constraints and demanding cycle times .

• Equipped with proximity sensors for effortless stroke tuning and operational verification .

• Built-in check valves for self-locking and pressure relief valves, ensuring sustained clamping pressure and system safety

• Rear-end screw mount facilitates easy installation and maintenance .

• Drain port design requires independent return-line connection to prevent back-pressure.

This fully integrated clamping system - from the Finger Power Chuck(2J type) to the Short Type Rotary Hydraulic Cylinder with Stroke Control and Safety Device(RS type) and sensing equipment is precision-engineered to meet the specific demands of irregular workpiece machining. It not only addresses positioning challenges but also significantly enhances machining efficiency and stability, making it an ideal solution for high-precision applications.