Manufacturing Capacity

Based in Changhua, Taiwan, AUTOGRIP provides comprehensive OEM manufacturing solutions, covering the full spectrum from precision machining, grinding, and multi-axis turning/milling to final assembly, quality assurance, and smart warehousing. We are committed to delivering high-precision, reliable, and traceable products with flexible lead times.

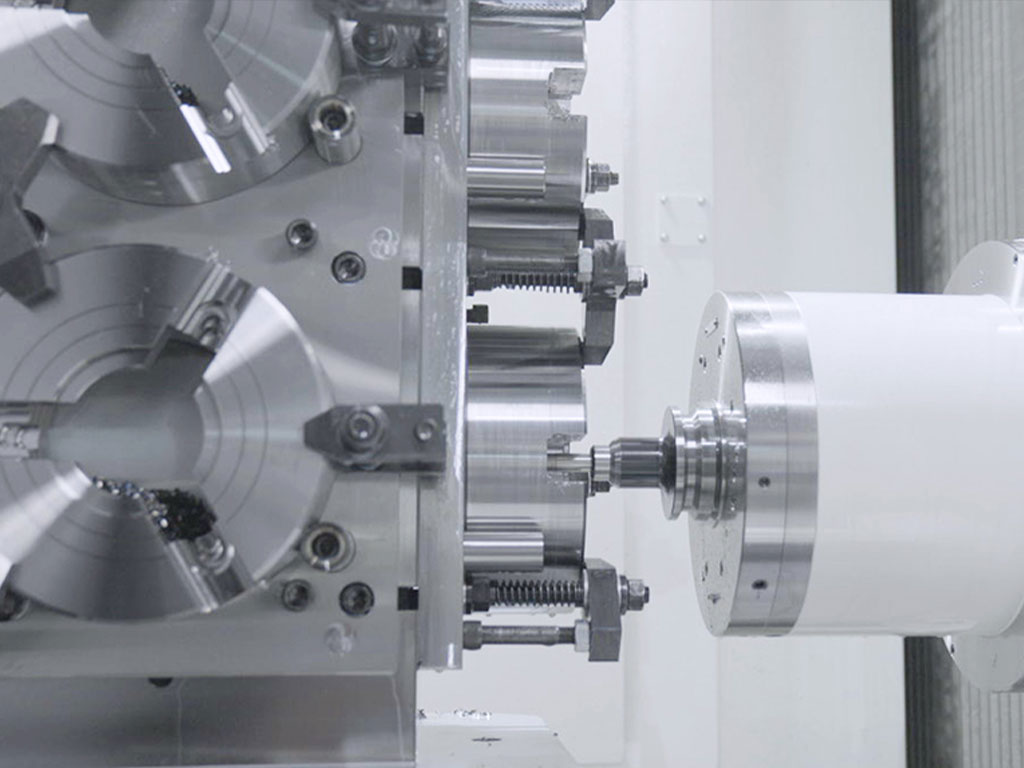

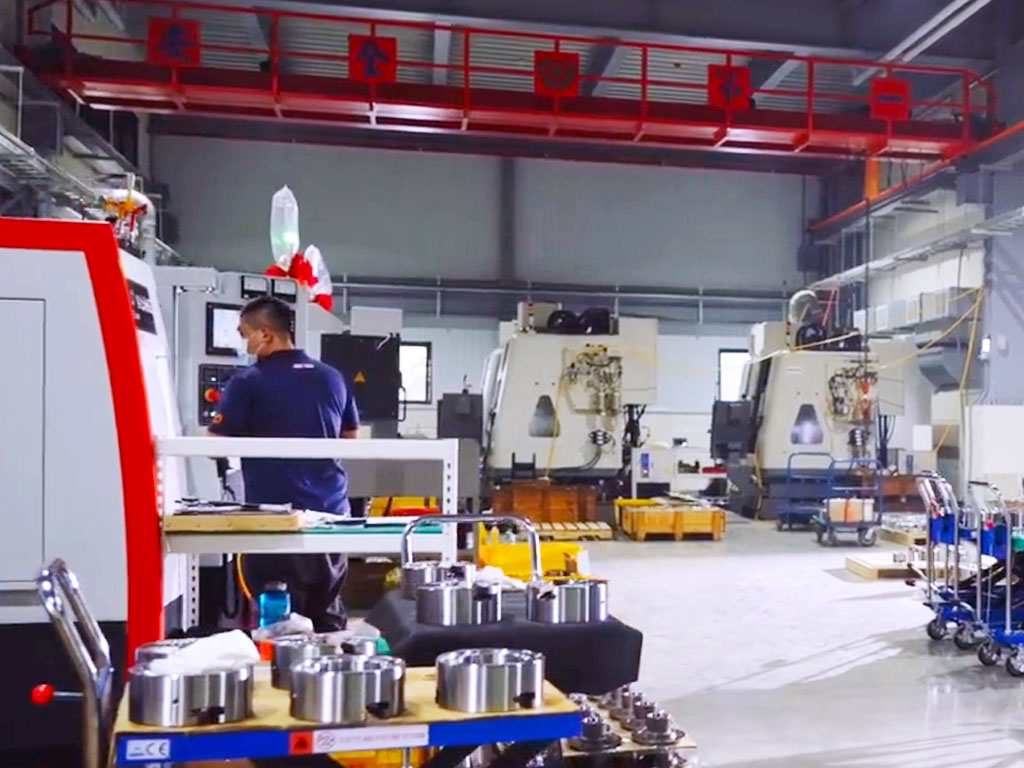

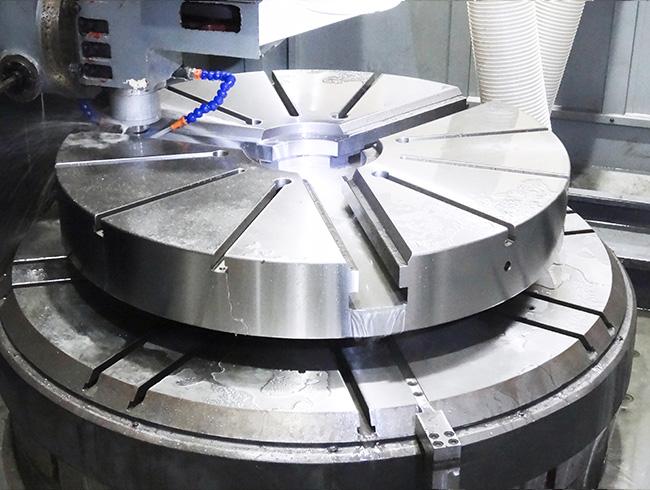

Turning & Milling Department|Multi-Axis Machining Solutions

Located in Changhua, Taiwan, AUTOGRIP’s Turning and Milling Department is equipped with a temperature-controlled facility to maintain thermal stability and dimensional accuracy throughout the machining process. Our comprehensive equipment lineup supports turning, milling, multi-axis, and complex integrated machining, allowing us to flexibly meet a wide range of workpiece and process requirements.

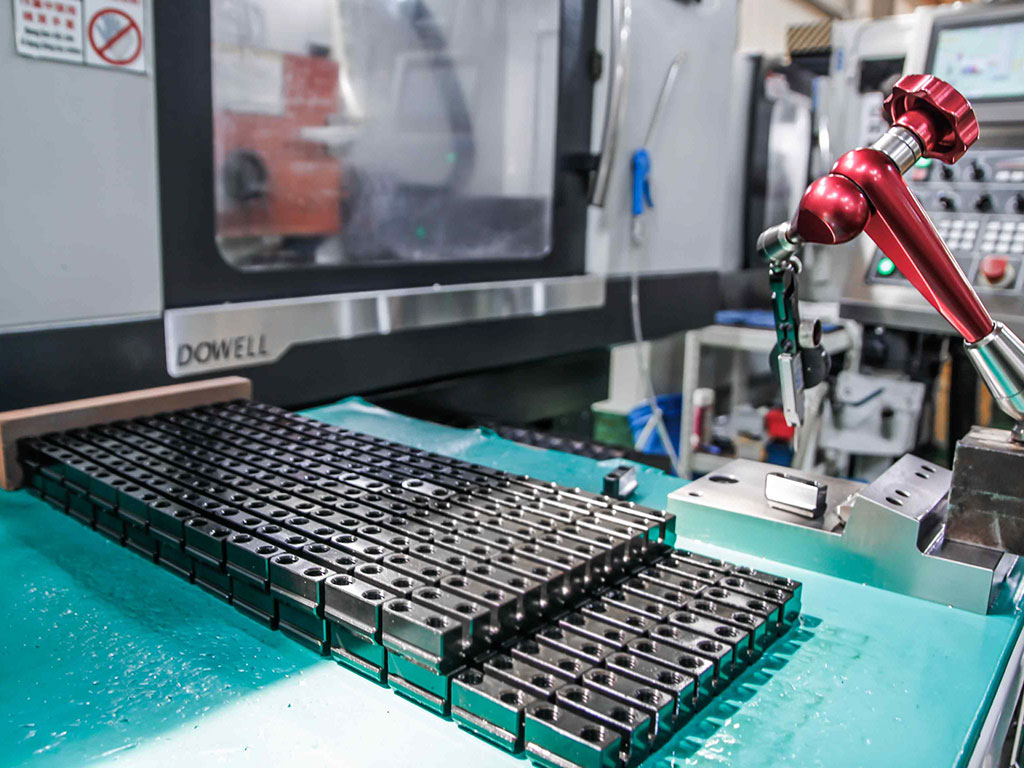

Precision Grinding Services in Taiwan|AUTOGRIP High Accuracy Machining

AUTOGRIP provides

precision grinding solutions

for global clients seeking

high-accuracy machining

. Our

temperature-controlled grinding facility

ensures stable dimensional tolerances by minimizing thermal deformation during processing.

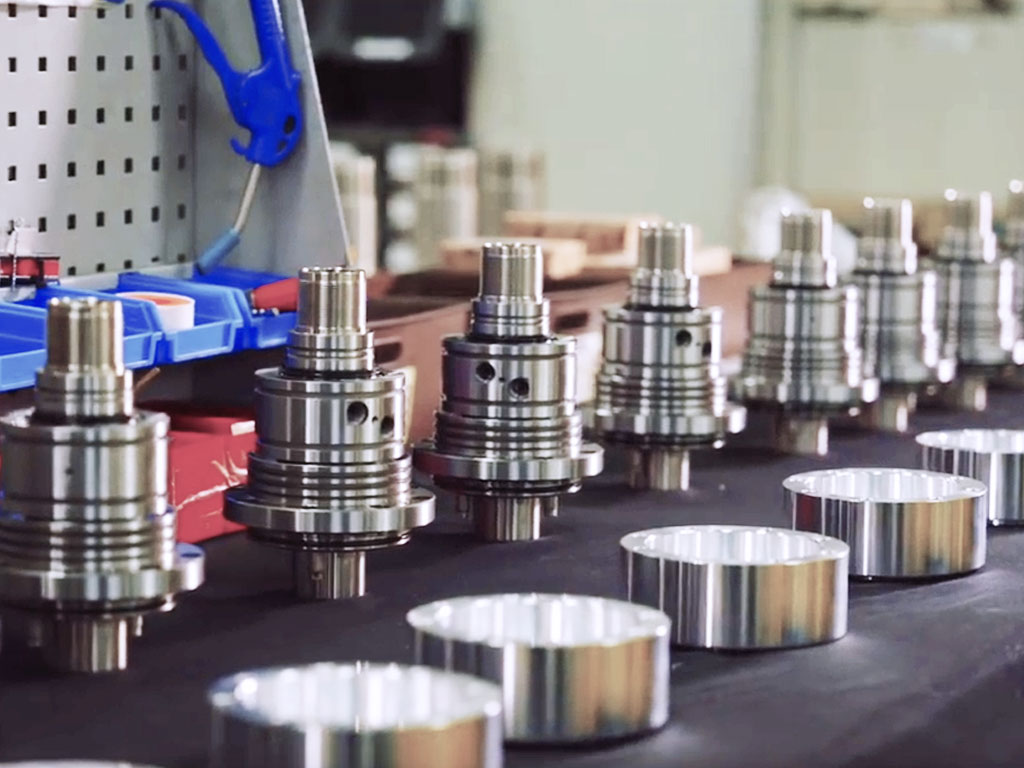

Assembly Department|Precision Assembly Solutions

AUTOGRIP’s Assembly Department in Changhua, Taiwan, features a climate-controlled assembly room to minimize environmental impact on product quality while ensuring a safe and comfortable workspace. The department is equipped with 8 independent workstations, delivering a monthly capacity of up to 3,000 units with flexible and efficient production capability.

Quality-Controlled Assembly Process

-

Professionally Trained Staff: All assemblers undergo rigorous internal training and follow standardized procedures to ensure assembly accuracy and process consistency.

-

In-Process Quality Checks: Key dimensions, fits, and functional testing are performed using in-line measurement tools to meet design specifications at every step.

-

Standardized Documentation: Assembly procedures are governed by detailed SOPs to ensure repeatability, traceability, and uniform quality.

-

Ongoing Education & Improvement: Regular training enhances skills in process judgment, issue response, and quality control.

With a strong combination of systematic workflows and skilled personnel, our Assembly Department maintains high stability and excellent yield rates, ensuring every outgoing product meets the exacting standards of our global customers.

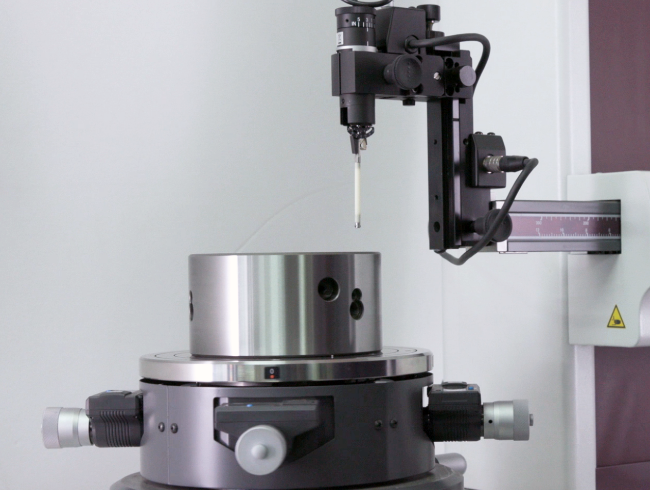

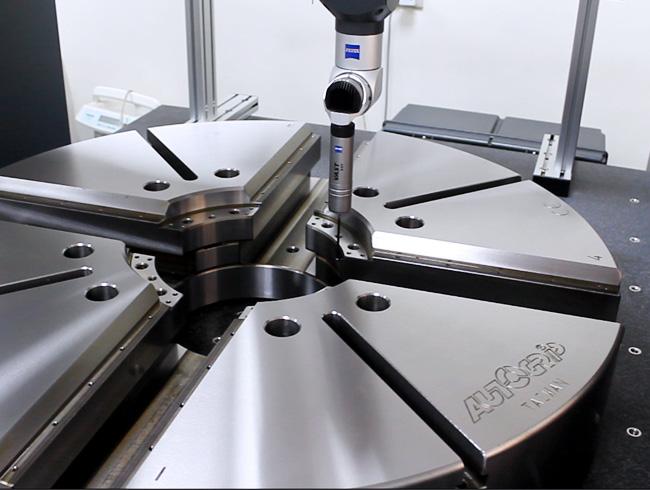

Quality Assurance Department|Certified Precision Quality Management

At AUTOGRIP, we uphold the principle of “Quality First”, operating under a comprehensive ISO 9001:2015-certified quality management system. Our products are also CE-certified, meeting the stringent safety and quality standards required in global markets.

Advanced Measurement Equipment

Our Quality Department is equipped with a full suite of high-precision instruments, including:

-

Coordinate Measuring Machine (CMM)

-

Roundness Tester

-

Contour Measuring Instrument

-

Height Gauges

-

2.5D Optical Measuring System

-

Hardness Tester

Additionally, we operate a mechanical testing laboratory certified under ISO/IEC 17025, capable of validating the strength and mechanical properties of raw materials and components.

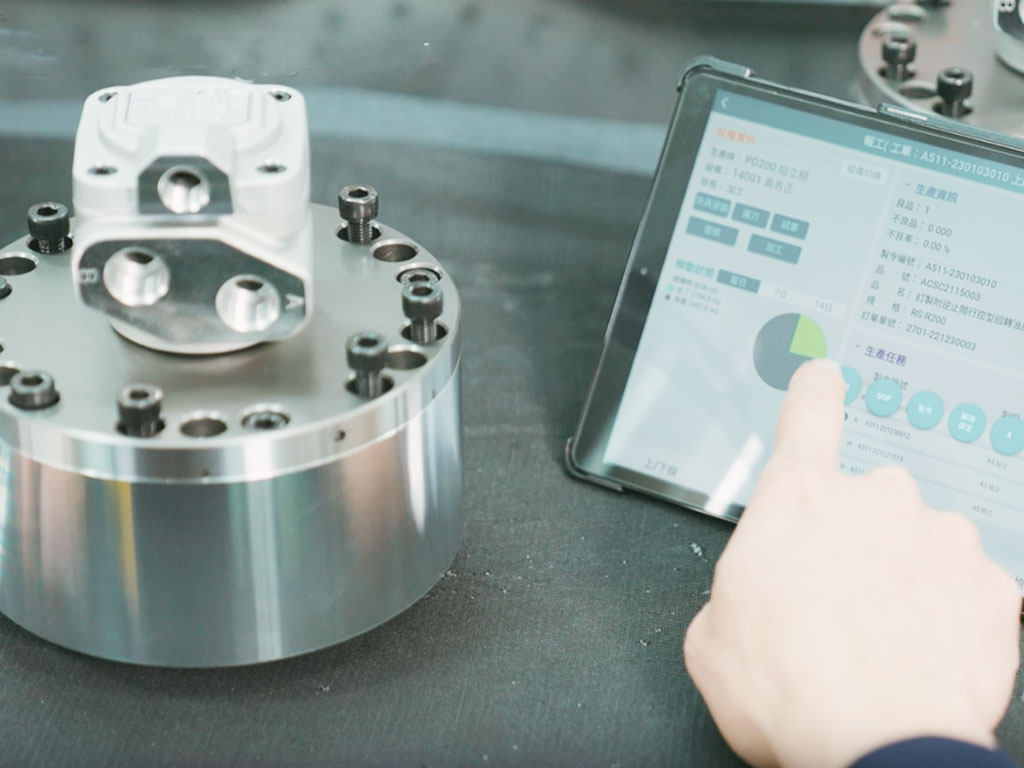

Warehouse Management|Smart WMS Logistics System

AUTOGRIP has fully implemented a WMS (Warehouse Management System) integrated with QR code and barcode scanning technology to digitize and streamline warehouse operations, improving both inventory accuracy and logistics efficiency.

The system enables real-time tracking of material movement and stock levels, automatically updating inventory records to reduce manual errors. With safety stock monitoring, it helps prevent both shortages and overstocking, ensuring stable turnover of raw materials and finished goods.

-

Real-time digital warehouse control

-

Faster response to production scheduling and order fulfillment

-

Accurate inventory levels, reduced waste and errors

-

Stronger supply chain agility and transparency

By leveraging smart logistics and automated tracking, AUTOGRIP ensures faster, more reliable delivery performance—providing customers with dependable and efficient supply chain support.