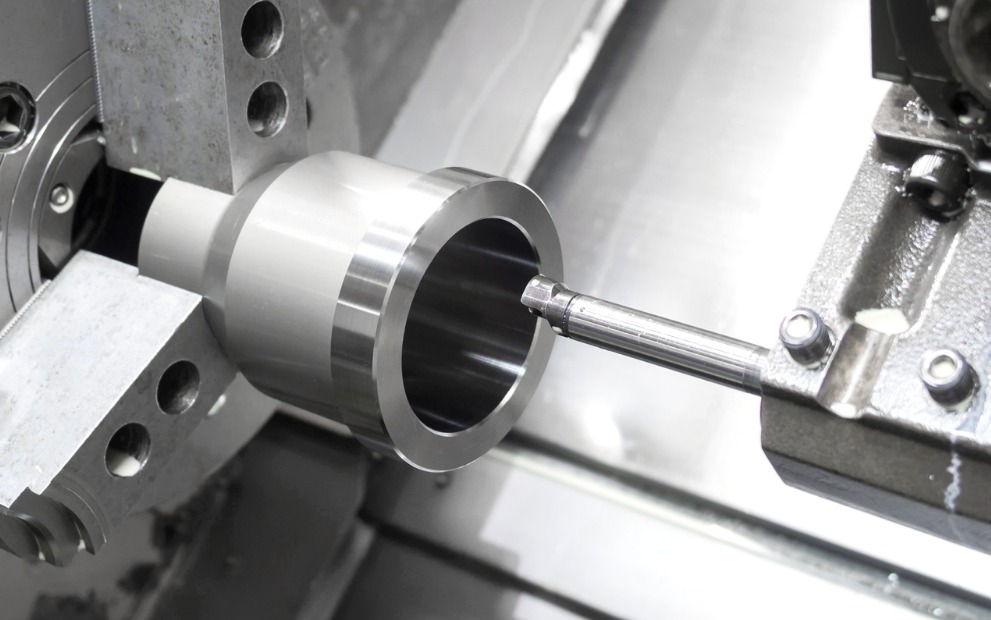

Turning Center

In turning operations, stable clamping is crucial for ensuring machining accuracy and efficiency. Chucks are indispensable clamping tools on turning centers, securing the workpiece to enhance stability and ensure high-quality turning results.

Application Cases

Why Are Chucks Essential for Turning Centers?

In turning operations, stable clamping is crucial for ensuring machining accuracy and efficiency. Chucks are indispensable clamping tools on turning centers, securing the workpiece to enhance stability and ensure high-quality turning results. Here are the main reasons why turning centers require chucks :

-

Ensures High-Precision Machining

Chucks deliver strong and stable clamping force, effectively minimizing runout, maintaining concentricity and surface finish—especially essential for precision turning of critical components. -

Enhances Clamping Stability and Safety

Chucks ensure that workpieces remain firmly in place during high-speed rotation, preventing slippage or ejection, reducing machine damage or scrap risks, and improving operational safety. -

Accommodates Various Workpieces and Machining Needs

Available in multiple types—power chucks, collet chucks, and special chucks—chucks can be selected based on the size, shape, and material of the workpiece, covering both standard and specialized applications. -

Reduces Changeover Time, Boosts Productivity

Quick-change chucks or automated clamping systems allow fast workpiece loading and unloading, reducing downtime and increasing production efficiency—ideal for mass production and automation. -

Improves Machine Rigidity and Durability

High-quality chucks feature excellent rigidity and wear resistance, capable of withstanding heavy-duty machining and extending the service life of the machine.

Chucks are critical components in turning centers. They not only ensure clamping stability and machining precision but also boost productivity and safety. By selecting the right chuck, turning operations become more efficient, reliable, and versatile.

Advantages of Pairing AUTOGRIP Chucks with Turning Centers

Turning centers are high-performance CNC turning machines used in metalworking across industries such as automotive, aerospace, and precision machinery. Choosing AUTOGRIP chucks significantly enhances machining efficiency and accuracy.

AUTOGRIP chucks provide stable clamping force and high precision, maintaining workpiece stability even at high speeds and reducing runout and machining errors. Their rigid design minimizes vibration, extends tool life, and lowers processing costs.

AUTOGRIP offers a wide range of chucks—including power chucks, rubber collet chucks, rotary hydraulic cylinder and special fixtures—ideal for various irregular and precision parts. With precise engineering and reliable quality, AUTOGRIP chucks are key tools for optimizing production on turning centers and boosting competitiveness.