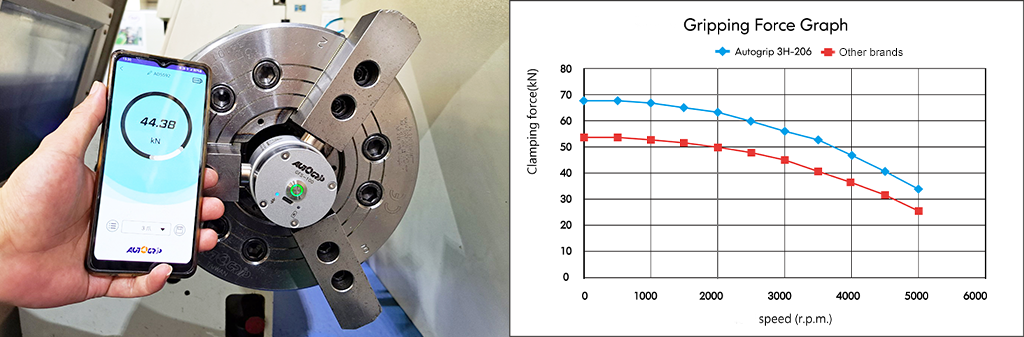

Dynamic Gripping Force Test

The curve of gripping force against rotary speed is obtained via force sensor at a given test condition.

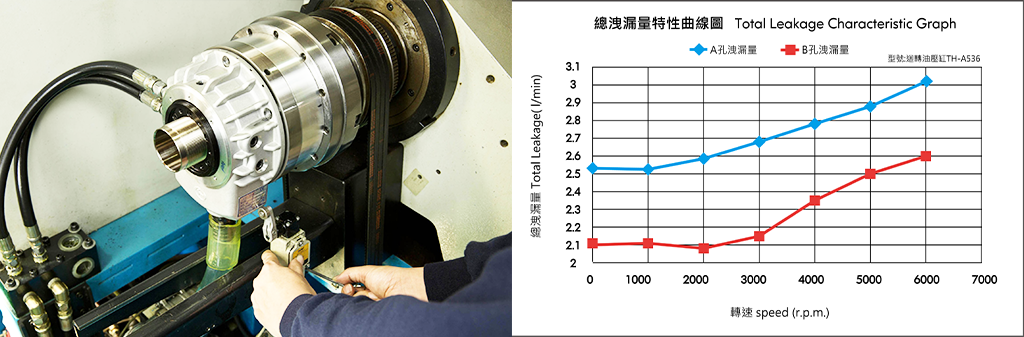

Dynamic Oil Leaking Test

The oil leaking of cylinder is measured at different rotary speed to ensure it is within engineering specification.

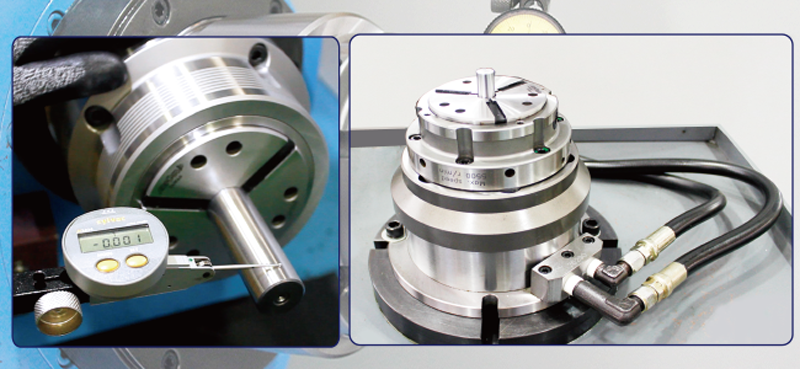

Rubber Collet Fatigue Test

- The finished product is installed on the testing machine to simulate the repeated opening and closing of the rubber cylinder clamp during the machining process, in order to test the wear resistance of the rubber cylinder clamp.

- Both the rubber cylinder clamp and the clamp body have passed the precision inspection on the machine.

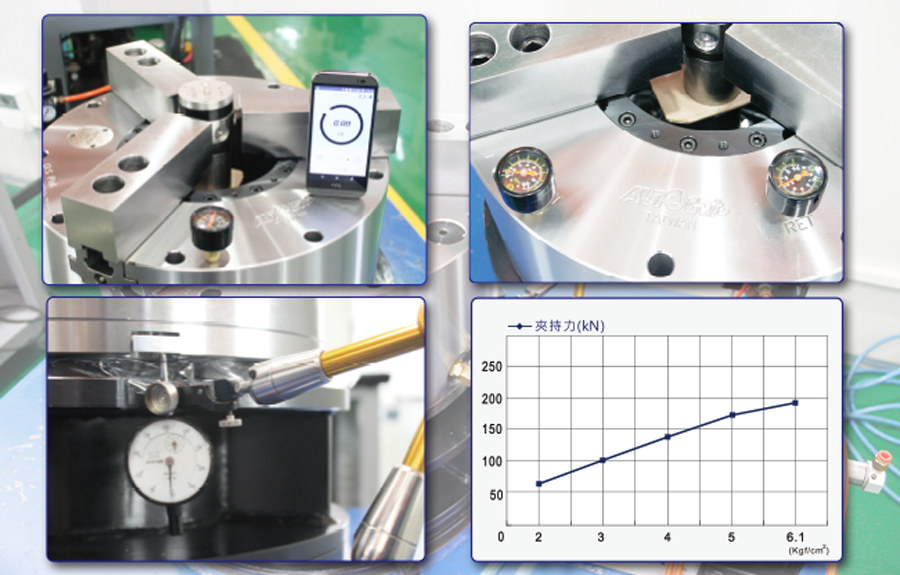

Pneumatic chuck Test

- Clamping Force Testing: Use a clamping force sensor to measure the clamping data.

- After the air pressure supply is cut off, test the product's pressure-holding performance.

- Pressure Detection: Test whether the pressure detection displacement is within the specified range.

Rubber Collet Fatigue Test

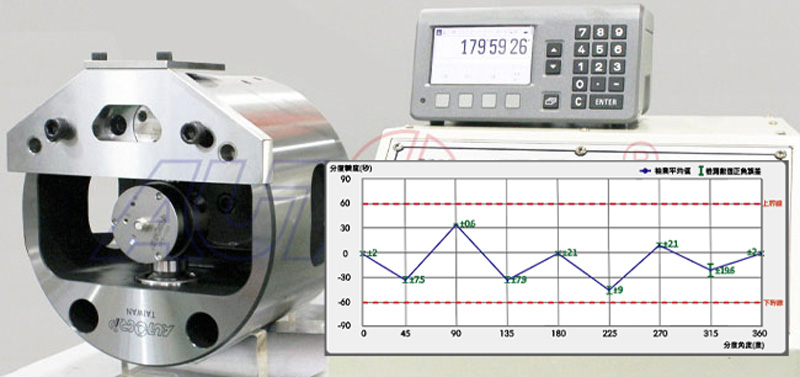

Using testing fixtures, ensure indexing accuracy according to the customer's machining requirements.