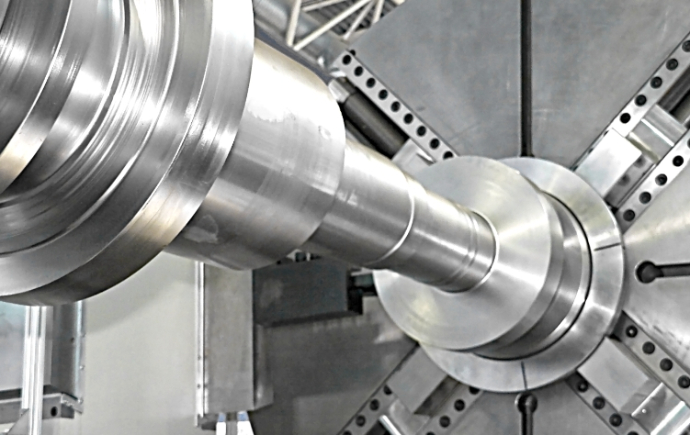

Special Purpose Machine

In Special Purpose Machines (SPMs), chucks are essential components that enable precise, efficient, and stable machining. SPMs are often designed to handle large volumes of complex workpieces or specific processing tasks. The function of a chuck goes beyond merely holding the workpiece—it also enhances machining accuracy, speed, and stability, ensuring smooth and efficient production.

Application Cases

Why Do Special Purpose Machines (SPMs) Need to Use Chucks?

In Special Purpose Machines (SPMs), chucks are essential components that enable precise, efficient, and stable machining. SPMs are often designed to handle large volumes of complex workpieces or specific processing tasks. The function of a chuck goes beyond merely holding the workpiece—it also enhances machining accuracy, speed, and stability, ensuring smooth and efficient production. Below are the main reasons why chucks are used in SPMs :

-

Enhancing Machining Accuracy and Stability

SPMs are typically designed for specific machining tasks such as precision grooving, compound machining, or multi-process operations. Chucks provide a strong and stable clamping force, ensuring that the workpiece remains secure without movement or deformation during high-speed rotation or multi-angle machining. This is crucial for parts requiring high precision, as it ensures consistent machining quality. -

Adapting to Complex Machining Requirements

SPMs often need to process irregular or non-standard workpieces that require cutting or machining from multiple angles. Chucks offer flexible clamping solutions—such as boring and grooving heads with expanding tools—that can stably position the workpiece for multi-surface machining, ensuring accuracy while reducing the risk of displacement. -

Efficient and Rapid Clamping Systems

SPMs generally require highly efficient automatic clamping systems to support continuous production and minimize changeover time. Using chucks allows for quick workpiece clamping and release, and when integrated with hydraulic systems, they enable fully automated machining—significantly boosting overall production efficiency. -

Minimizing Operator Intervention and Increasing Safety

Automated chuck designs reduce the need for direct operator involvement, which not only enhances productivity but also improves safety. For example, hydraulic chuck systems maintain a secure grip on the workpiece throughout the machining process, reducing the risk of loosening or accidents caused by improper operation. -

Increasing Machine Durability and Reliability

Chuck systems can be customized for various machining needs using high-quality materials and precision engineering to ensure long-term stable performance. High-performance products such as hydraulic systems and expanding grooving heads help reduce machine wear and extend the service life of SPMs.

Conclusion

The application of chucks in Special Purpose Machines not only improves machining precision and efficiency but also enables the handling of complex workpieces and challenging processing tasks. This enhances overall production stability and safety. From expanding grooving heads to hydraulic systems, AUTOGRIP offers a wide range of clamping solutions are including power chuck, CNC lathe collet chuck, hydraulic rotary cylinder and others that help SPMs perform efficient and precise machining, boost overall productivity, and extend equipment lifespan.