Innovative Workholding for Advanced Manufacturing

AUTOGRIP focuses on developing diversified and innovative workholding solutions to meet the needs of automated production. Recently, in cooperation with GOODWAY , we provided a machining solution for a dual-valve pipe fitting manufacturer in Bulgaria, aiming to enhance machining efficiency and dimensional accuracy.

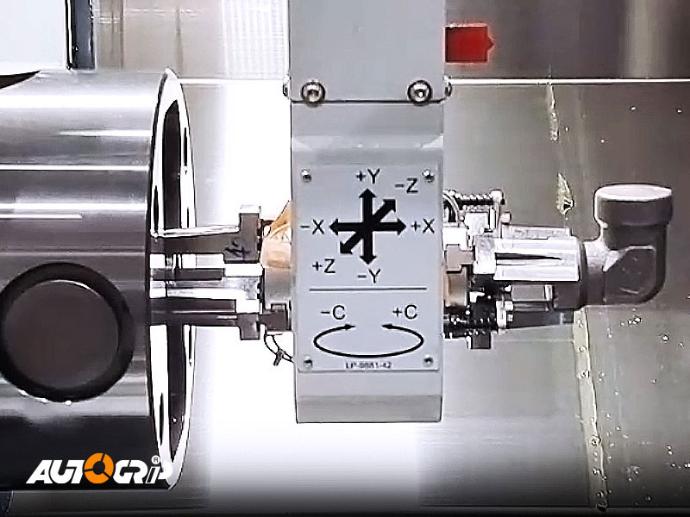

The IS-254 Automatic Indexing Chuck was the key workholding component enabling this solution.

Technical Advantages of IS-254 Automatic Indexing Chuck

- High-Speed Indexing: Performs fast 45° / 90° indexing operations while the spindle is running, enabling smooth and seamless multi-station switching.

- Seamless Integration: Works perfectly with the GOODWAY GA-2800 robotic arm for fully automated loading and unloading.

- Enhanced Productivity: Reduces manpower dependency and significantly improves production efficiency and process stability.

- High-Precision Manufacturing: Ensures consistent accuracy in every production step, meeting the demands of advanced manufacturing.

Application Results

By combining the IS-254 Automatic Indexing Chuck with the GA-2800 robotic arm, the customer achieved:

- Automated loading/unloading → reduced cycle time and operator dependency

- Multi-station indexing → eliminated additional fixture changes and reduced downtime

- Stable and repeatable clamping → improved overall machining precision and productivity

This application demonstrates how the IS-254 can support multi-axis machining, robotic handling,

and automated production lines, helping manufacturers achieve higher throughput and reliability.