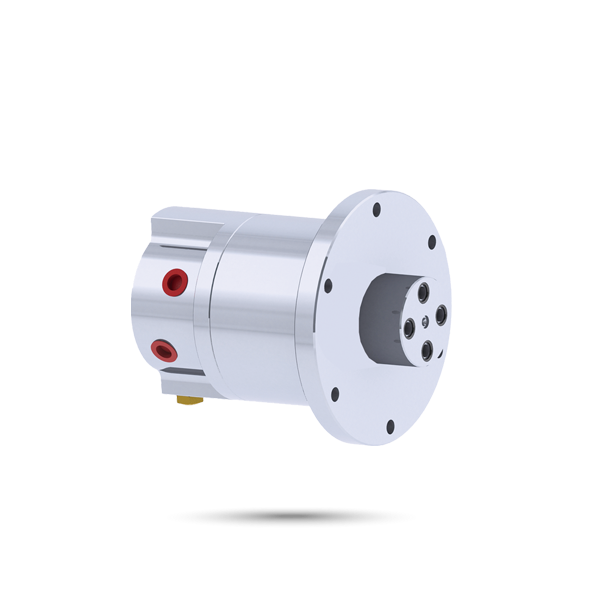

In many mechanical systems, when fluid, air, or hydraulic pressure must be transferred between stationary and rotating components, the Rotary Joint becomes the critical element that ensures reliable flow and sealing performance.

AUTOGRIP possesses comprehensive capabilities in design, manufacturing, and testing, enabling us to deliver both standard and customized rotary joint solutions. Each solution is tailored to meet the specific requirements of speed, pressure, medium type, and installation constraints in our customers’ applications.

Technical Features and Advantages

- Supports single-channel, multi-channel, and mixed-medium (air + hydraulic oil, water, coolant) transmission.

- Maintains stable sealing performance under high speed and high pressure conditions.

- Provides customizable interface dimensions, channel configurations, and material selections.

- Utilizes high-precision bearings and reinforced sealing structures for long-term durability.

- Every unit is pressure-tested and dynamically inspected to ensure consistent reliability.

Application Fields

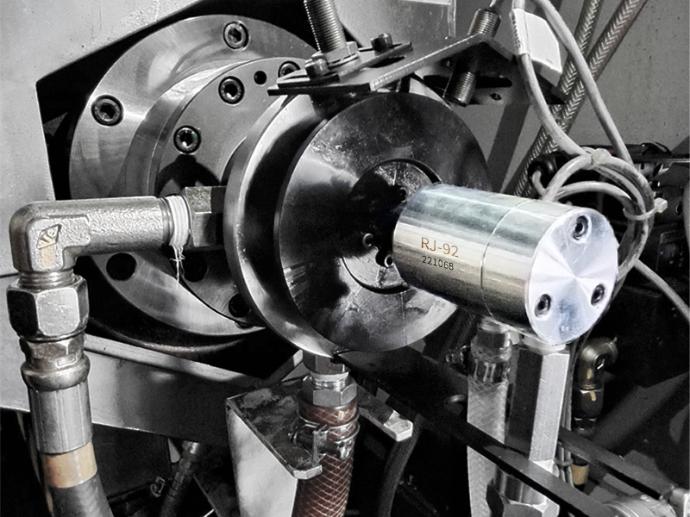

- CNC lathes and turning center spindles

- Hydraulic rotary cylinders and power chucks

- Rotary tables, indexing systems, and coolant supply lines

- Other automation systems requiring rotary fluid transfer

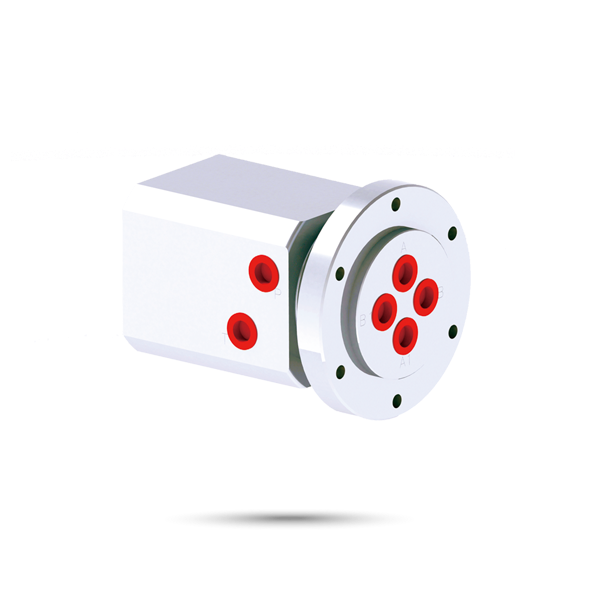

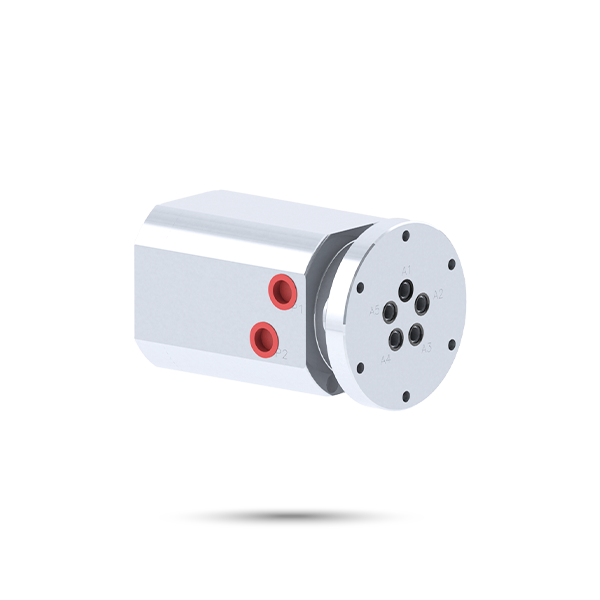

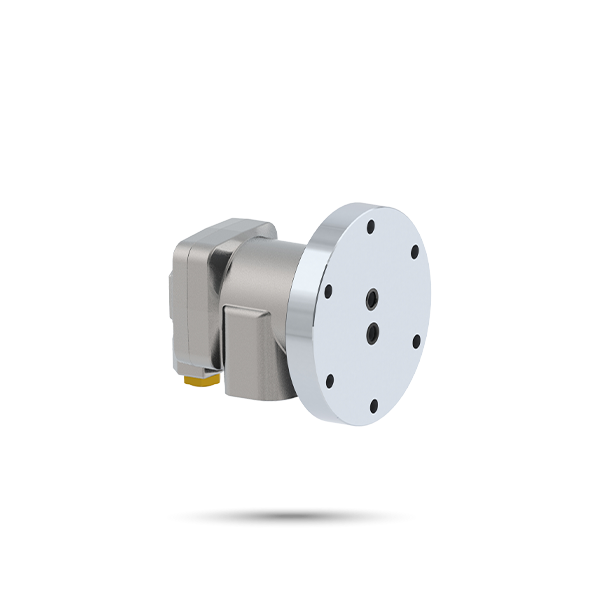

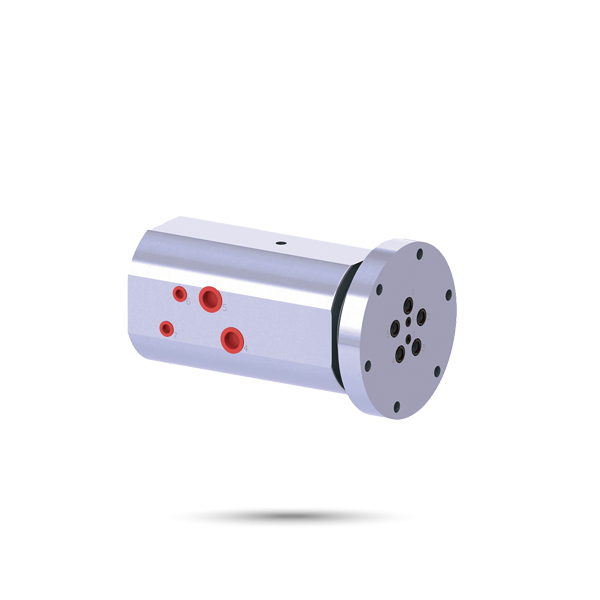

Typical Models (Customizable

upon Request)

These cover a wide range of rotary transmission requirements—from single-channel air systems to complex multi-fluid hydraulic configurations.

For non-standard flanges, higher pressure ratings, or additional channel designs, AUTOGRIP offers full customization and engineering support.

With decades of experience in workholding and rotary transmission technology, AUTOGRIP delivers precise, reliable, and application-specific rotary joint solutions.

Whether for single-channel pneumatic transfer or complex multi-fluid hydraulic systems, we ensure stable performance and long service life even under demanding operating conditions.