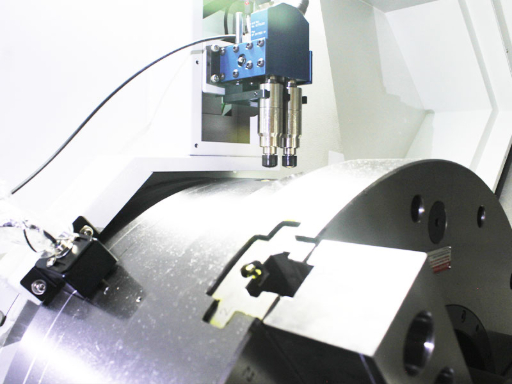

In the machining of large or long workpieces, stability and accuracy are constant challenges. Jashico Machine machines are equipped with AUTOGRIP Large Thru-Hole Air Chuck (AP- Series), adopting a dual-chuck configuration that effectively grips large and long workpieces.

This design successfully resolves the common issues of instability, vibration, and uneven stress encountered with a single chuck during high-speed rotation or heavy cutting, ensuring machining precision and safety.

Advanced Air Supply System

The advanced Air Supply System fundamentally improves the installation and maintenance challenges commonly associated with conventional sealing ring designs.

This innovative system significantly simplifies installation, reduces maintenance time and costs, and represents a major breakthrough in air supply and sealing performance within the industry.

Stable, Precise, and Safe

- Front main chuck: grips the front end of the workpiece for machining.

- Rear sub chuck: grips the rear end of the workpiece, providing extra support to prevent deflection or vibration during high-speed rotation.

- The rigid structure, which is compliant with CE standards, ensures high accuracy and rigidity for a reliable machining foundation.

- Multiple safety features:

▩ Built-in pressure detection for real-time clamping status detection, preventing accidents caused by unstable clamping.

▩ Water and chip-proof design to effectively block coolant and chips, extending product lifespan.

With the AUTOGRIP Large Thru-Hole Air Chuck (AP- Series) , the dual-chuck solution applied on Jashico Machine machines ensures machining precision, safety, and efficiency for large and long workpieces, delivering a high-performance and reliable solution for the manufacturing industry.

Related Products:

Large Thru-Hole Air Chuck (AP type)