Customer Needs

An EV component manufacturer, facing rapidly increasing orders, aimed to achieve 24/7 automated machining on their existing equipment.

The original CNC lathe used a conventional clamping system, lacking sufficient gripping force and low efficiency, unsuitable for continuous production and dual-end machining.

AUTOGRIP Solution

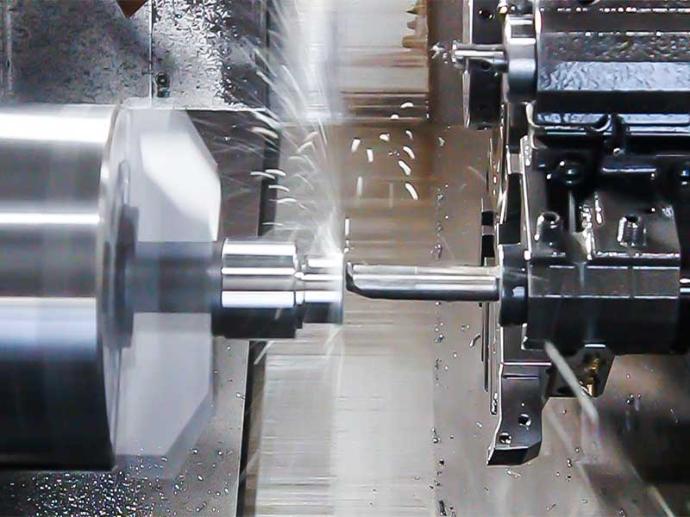

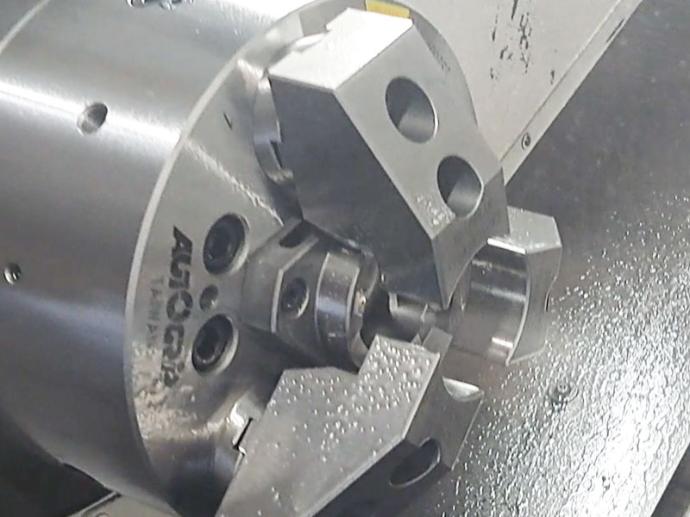

Large Thru-hole Power Chuck (3H-208)

Applied for the front-end machining of workpieces, the large bore design allows bar and shaft machining with strong clamping force and stable precision.

Customized base jaws and soft jaws are applied to increase the clamping contact area and minimize deformation, ensuring concentricity and stability.

A single-channel hydraulic cylinder with coolant-through spindle delivers coolant directly into the workpiece and cutting zone. This effectively improves chip evacuation, reduces cutting heat, and extends tool life, making it ideal for long-shaft or deep-hole machining.

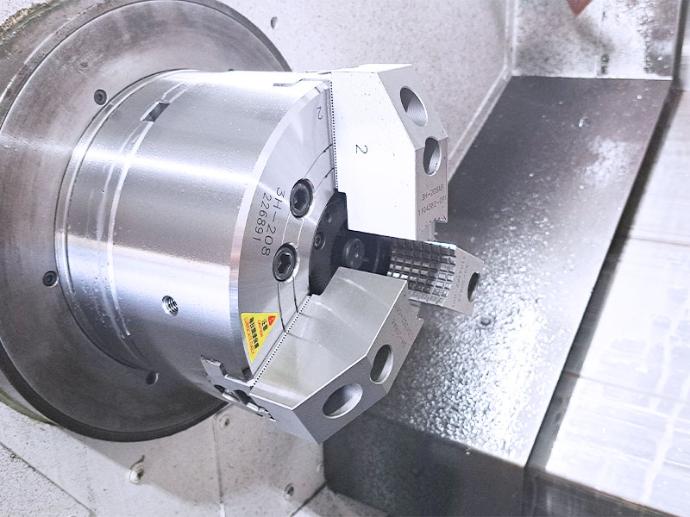

Pull Down Power Chuck (3D-08K)

Applied for rear-end machining, the pull-down mechanism prevents workpiece lifting, ensuring high concentricity—perfect for dual-end turning.

Paired with RC-125S-F2 Hydraulic Cylinder, featuring internal center coolant supply and external air-seal detection:

- Airtight pressure detect: Verifies proper workpiece clamping to prevent slippage, ensuring production stability and safety.

- Coolant through spindle: Delivers coolant directly into the machining area, improving chip evacuation, reducing heat, and extending tool life.

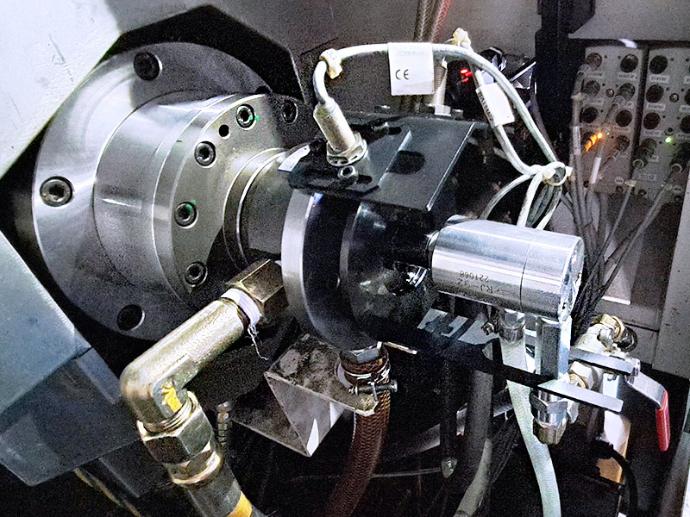

Hydraulic Cylinder with Rotating Joint (RC-type)

Provides stable hydraulic transmission, ensuring reliable chuck performance under high-speed rotation and long-duration machining.

Configured with single-channel or dual-channel rotating joints depending on application:

- Single-Channel(RC-125S-M1): For Large Thru-hole Power Chuck (3H-208), for center coolant or single hydraulic control.

- Dual-Channel( RC-125S- F2): For Pull Down Power Chuck (3D-08K), supporting both center coolant and air-seal detection.

One cylinder, multiple joint options, flexible to meet diverse machining requirements.

Robotic Loading & Unloading

The robotic arm automatically replaces wheel axle workpieces, enabling 24/7 uninterrupted production, significantly reducing labor costs and enhancing efficiency.

Results & Advantages

- Machine Upgrade & Cost Optimization : Extended the service life of existing equipment by replacing chucks and hydraulic cylinders, avoiding the high investment of purchasing new machines.

- Dual-End Machining Capability : Combination of Large Thru-hole Power Chuck and Pull Down Power Chuck enables precise dual-end machining of shaft workpieces, ensuring concentricity and dimensional accuracy.

- Integrated Cooling & Detection : Single/dual-channel rotating joints support center coolant supply and air-seal detection, improving cutting efficiency, tool life, and machining safety.

- Fully Automated Production Line : With robotic loading and unloading, the system achieves 24/7 unmanned production, reducing labor dependency and ensuring consistent productivity.

- High Precision & Yield : Enhanced machining stability meets the stringent quality standards of EV components.