As aluminum wheel manufacturing continues to demand higher precision, consistency, and automation, the stability of the workholding system and its integration across processes have become critical factors affecting production efficiency and quality.

AUTOGRIP Machinery, leveraging decades of expertise in power chucks and

customized workholding solutions, has partnered with Victor Taichung to jointly

develop a series of dedicated workholding systems for aluminum wheel

machining, successfully implemented in an automated production line.

This aluminum wheel chuck series is specifically designed to match Victor Taichung’s vertical turning centers and vertical machining centers. By integrating OP1 to OP3 processes, a single production line can simultaneously complete turning, drilling, and measurement operations for 16-

inch

, 17-

inch

, and 18-inch aluminum wheels, significantly enhancing production flexibility and overall efficiency.

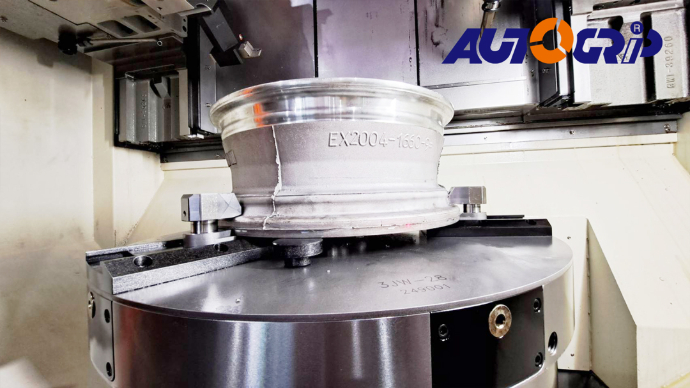

Stable Clamping Across the Entire Process

At OP1, AUTOGRIP’s 3JW-28 aluminum wheel power chuck provides automatic self-centering for 16-

inch

, 17-

inch

, and 18-inch wheels. Equipped with high-strength carbide gripping jaws for face clamping, it ensures precise positioning during center hole and outer profile machining. An integrated airtight pressure detection function continuously monitors clamping status, enhancing automation reliability and operational safety.

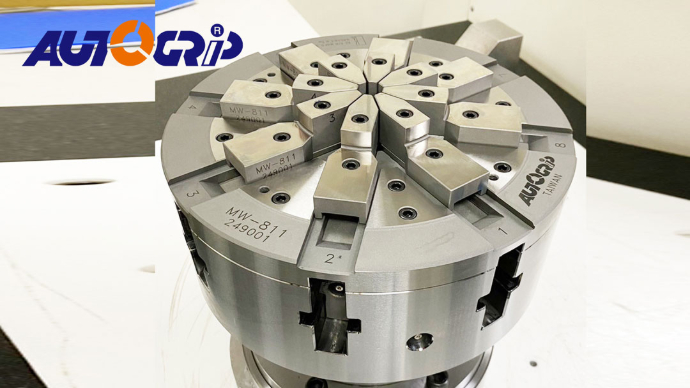

For center hole measurement, the MW-811 wheel measurement chuck utilizes an 8-jaw concentric internal support design combined with a chip-blowing dust protection mechanism. This configuration effectively eliminates chip interference and ensures stable, high-accuracy measurements for hub diameters ranging from Φ50 to 150 mm.

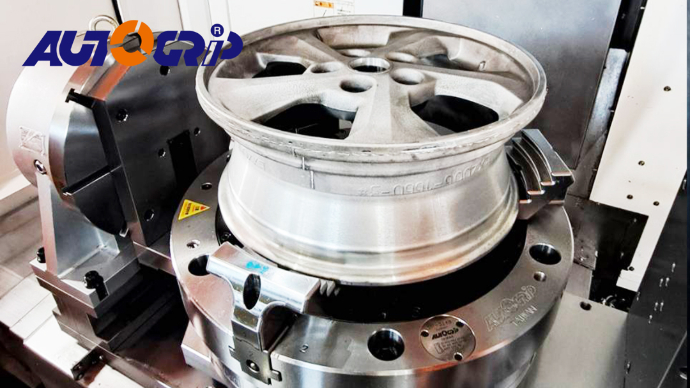

Designed for High-Load, Long-Term Production

In OP2 and OP3 finishing stations, AUTOGRIP introduces the 6PW-25A11 and SHW-324B aluminum wheel chucks. Their fully sealed construction prevents coolant ingress, reduces maintenance requirements, and extends service life. Different wheel sizes can be machined without changing jaws, significantly improving line changeover efficiency.

The SHW-324B further incorporates a vacuum dust-proof

design, preventing chips from entering the chuck during PCD and air valve hole

machining, ensuring stable operation and consistent clamping performance over

extended production runs.

Customized Collaboration Showcasing System Integration Value

According to AUTOGRIP, this aluminum wheel chuck series was jointly developed as a project-specific solution based on Victor Taichung machine specifications and actual production requirements. The design emphasizes clamping stability, automation integration, and mass production feasibility.

These chucks are exclusively designed for use with Victor Taichung machines and are not available for standalone sale, serving as a collaborative showcase of integrated automation solutions.

AUTOGRIP will

continue to focus on “High-Precision Workholding × Customized Applications,”

strengthening partnerships with machine tool builders to deliver comprehensive

and competitive workholding solutions for aluminum wheel machining and other

high-value manufacturing sectors.