In this application,

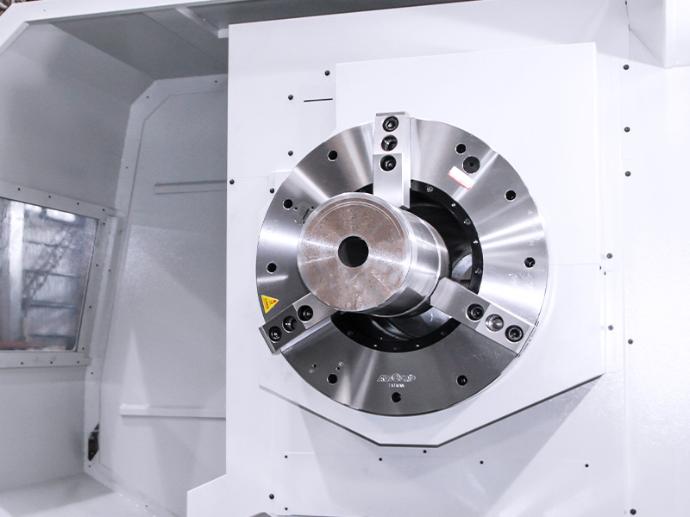

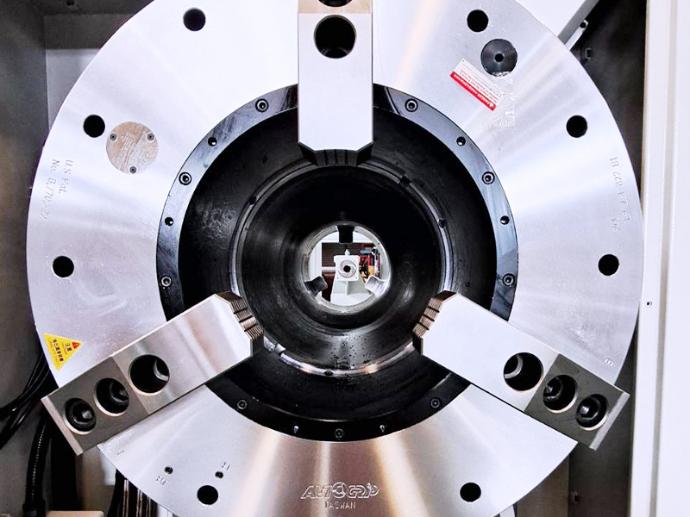

the AUTOGRIP AP-375 large

thru-hole air chuck is installed on a MYDAY Machinery CNC precision

oil-tube lathe to support heavy-duty tube machining.

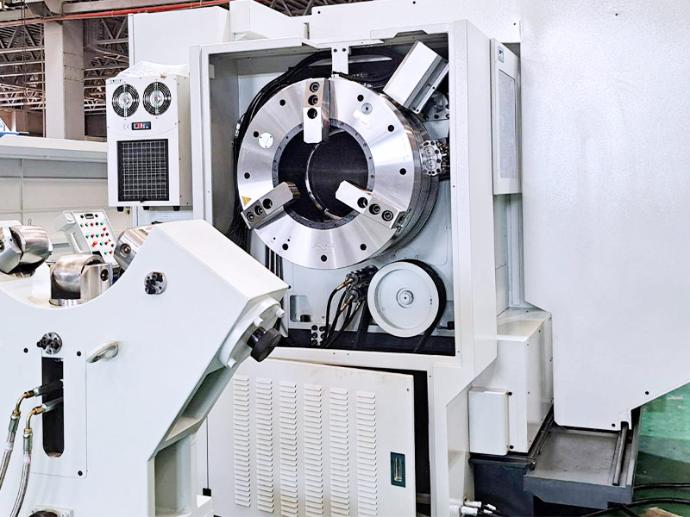

The system utilizes a dual-chuck

configuration, where the front and rear chucks work in sequence

to ensure secure clamping during machining of long oil tubes.

The oil tube is fed from the rear side and the extended tube is supported by a rear hydraulic steady rest, allowing stable machining of long and heavy workpieces.

Solution Features

- Large Thru-Hole Pneumatic Chuck Design

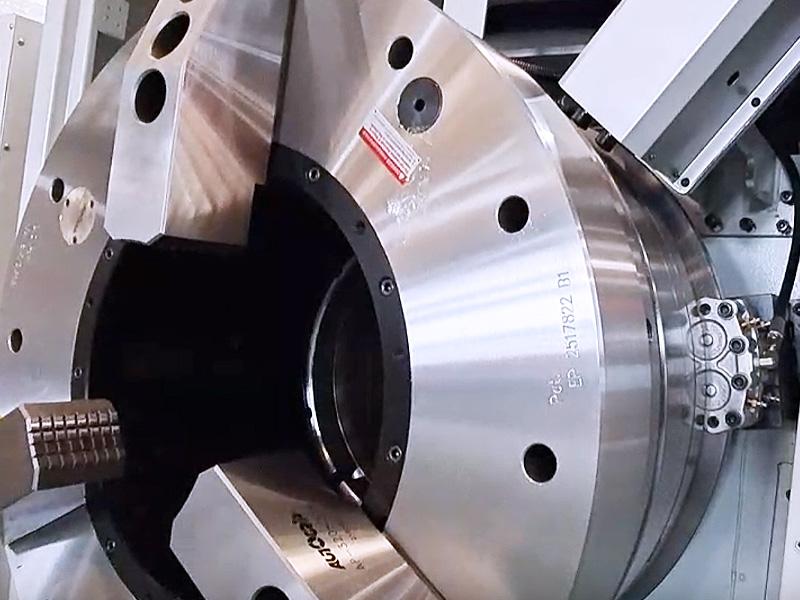

The AP-375 integrates an internal air cylinder to deliver stable and high clamping performance.It's large thru-hole design is ideal for processing long tubes, oil pipes, and both hollow or solid bar materials. - Built-in Pressure Monitoring Mechanism

The chuck incorporates an internal pressure-sensing mechanism that detects abnormal pressure drops, ensuring operational safety and preventing accidental workpiece slippage during machining. - AUTOGRIP air supply system

The air-supply design eliminates the need for conventional sealing rings, significantly reducing installation time and avoiding seal-ring failure issues—ultimately lowering maintenance and machine downtime costs. - Compatible With C-Axis Positioning

When combined with machine C-axis positioning, the clamping sequence achieves accurate alignment and ensures stable, repeatable machining operations.

Machining Benefits

By implementing this dual-chuck clamping setup with steady-rest support, the customer achieved:

- Higher machining efficiency

- Reduced time for manual refixturing and repositioning

- Improved operational safety

- Stable long-duration machining performance

This application demonstrates AUTOGRIP’s expertise in automated tube-machining clamping

solutions, helping customers enhance productivity and maintain

high accuracy in demanding oil-tube machining processes.

Related Products: Large Thru-Hole Air Chuck (AP type)