Maximize Performance with

Precision, Stability, and Productivity

To meet the demands of high-precision machining and versatile clamping applications, AUTOGRIP proudly introduces its new precision vise lineup :

MVSC : 5-Axis Self-Centering Vise

MVRH : MC Hydraulic Vise

MVRE : MC Power Vise

All three models are made in Taiwan, engineered with high-rigidity structures, precision guideways, and consistent clamping performance. They are ideal solutions for applications ranging from 5-axis machining to MC setups, making them essential tools for machining and equipment integration.

MVSC : 5-Axis Self-Centering Vise

Designed for 4-axis, 5-axis, and multi-face machining, the MVSC features a unique synchronized drive mechanism that delivers self-centering clamping. This ensures secure and concentric workpiece positioning, making it ideal for high-precision components. The low-profile, interference-minimized body design enhances tool accessibility and eliminates collision risks—an optimal choice for aerospace, medical, and precision mold industries.

MVRH : MC Hydraulic Vise

The MVRH is manually operated via a handle-turned leadscrew, integrated with a precision hydraulic mechanism to deliver strong, stable clamping with minimal effort. Its high-rigidity body and precision slide system guarantee excellent repeatability, making it suitable for CNC Horizontal Machining Centers (HMCs) and other machine tools. Widely adopted in automotive parts production and mass-processing lines requiring high efficiency and stability.

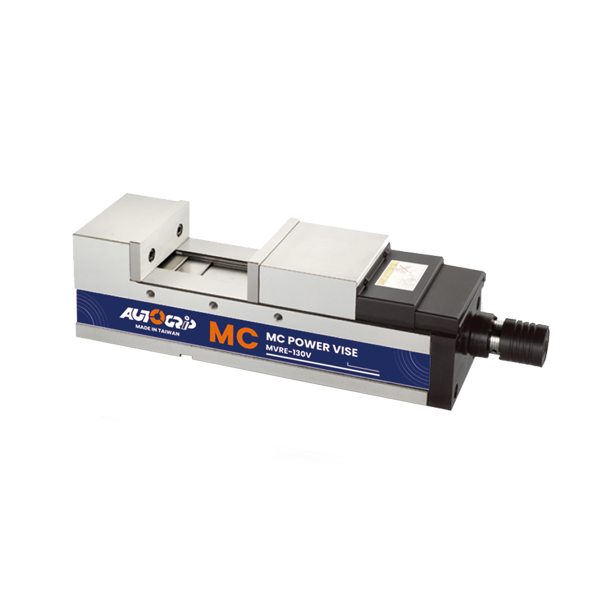

MVRE : MC Power Vise

The MVRE is equipped with a mechanical power-boost mechanism, enabling extraordinary clamping force with effortless manual operation. Its unique two-stage boosting system ensures firm grip even during high-speed or heavy cutting, while minimizing the risk of workpiece deformation. Ideal for clamping aluminum, plastic, or thin-walled parts, it strikes the perfect balance between force and precision—highly favored in the precision manufacturing sector.

Discover more