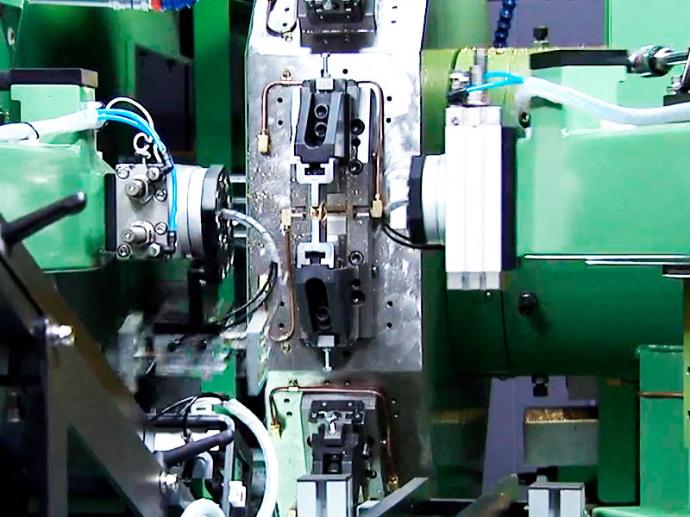

Plumbing hardware products such as faucet bodies, valve housings, and pipe fittings are often manufactured from brass or stainless steel blanks. During machining, multiple surfaces and features must be processed simultaneously, with strict requirements for dimensional accuracy and sealing performance. Traditional clamping methods may struggle with complex shapes or repeated re-clamping, leading to errors and reduced productivity.

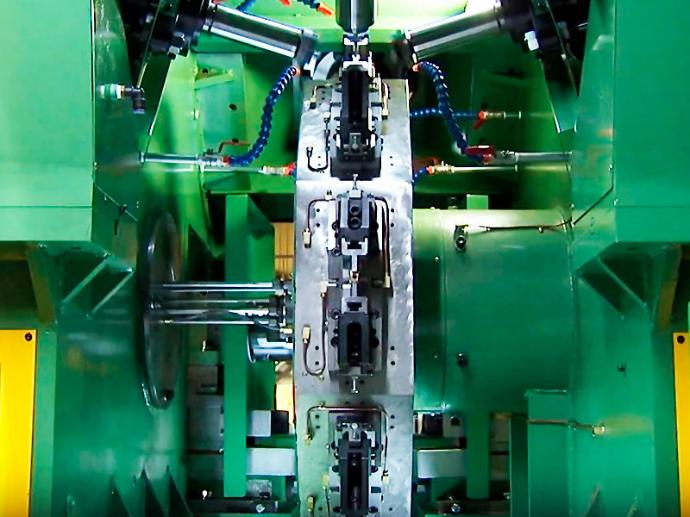

AUTOGRIP’s synchronous clamp provides a reliable clamping solution for multi-axis rotary tables and trunnion-type multi-spindle machining centers. It is particularly well-suited for plumbing hardware manufacturing, ensuring stable positioning and high machining efficiency.

Key Advantages

- Single Setup, Multi-Surface Machining:

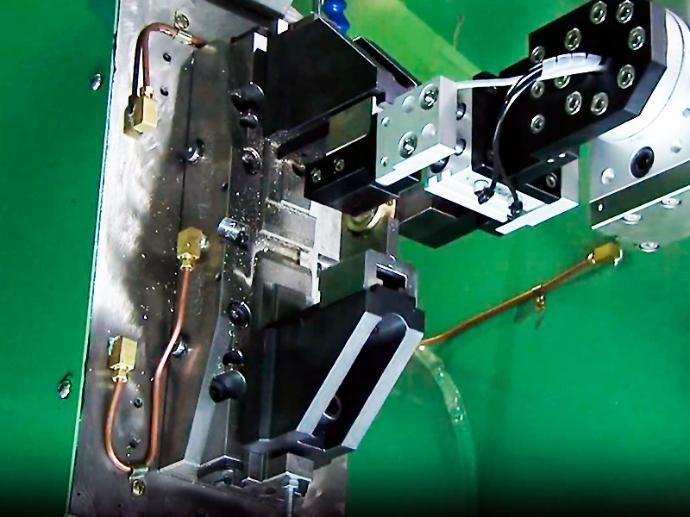

Eliminates errors caused by repeated re-clamping, improving consistency. - Long Jaw Stroke:

Accommodates various blank sizes, enhancing process flexibility. - High Accuracy with Dust Protection:

Ensures precise hole machining while resisting chips and coolant intrusion. - Cost Reduction & Efficiency Boost:

Shortens machining cycles, reduces scrap and rework.

By minimizing clamping errors, the synchronous clamp supports both small-to-medium batch multi-process machining and long-hour automated production, delivering stable and reliable performance.

Applied Machine: Hann Kuen Machinery & Hardware Co., Ltd.

Related Products: Synchronous Clamp (CP type)