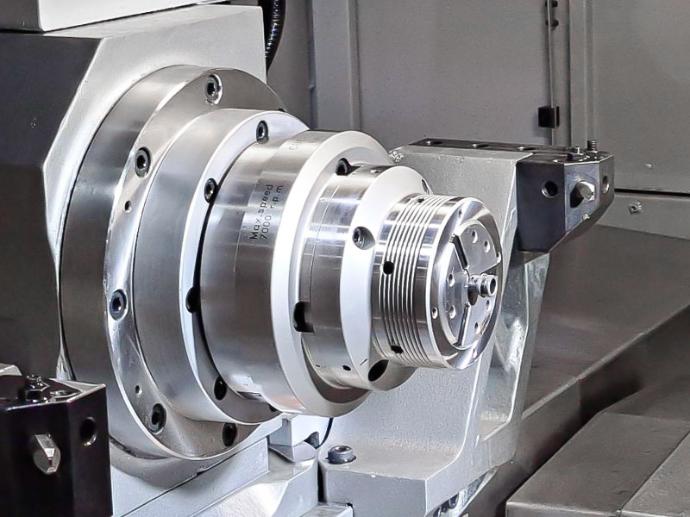

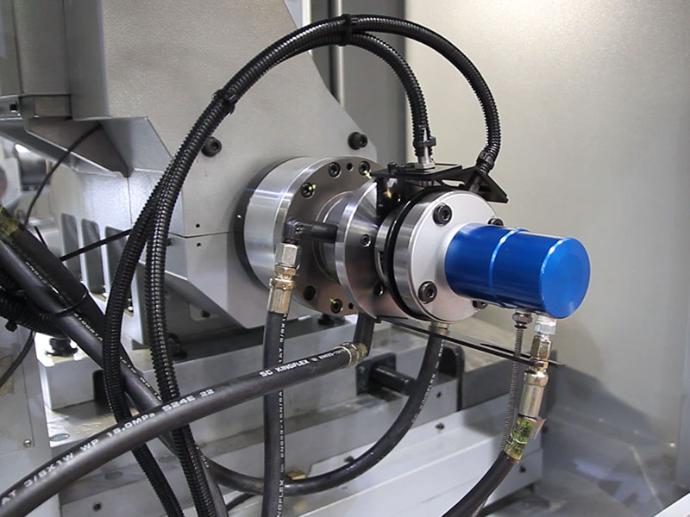

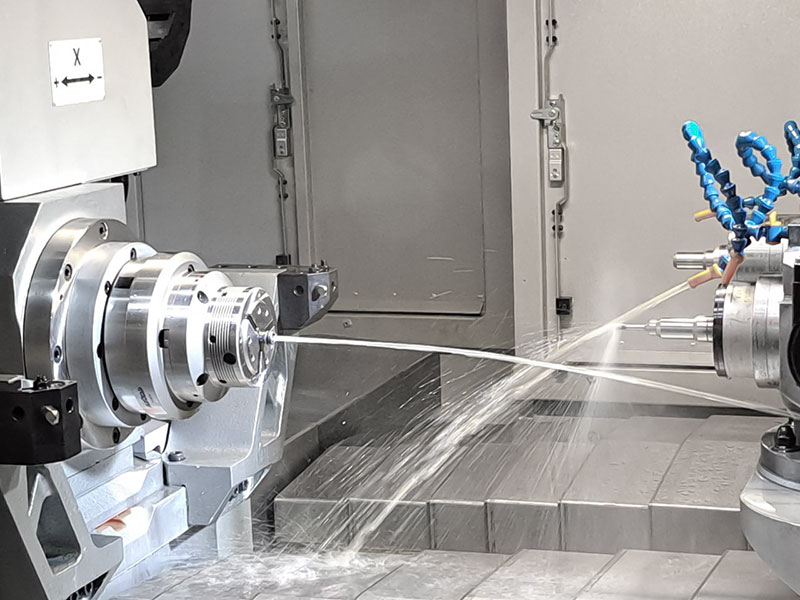

AUTOGRIP End-Stop Rubber Grip Collet Chuck (CBE/CBE-A) paired with the Rotary Hydraulic Cylinder with Rotating Joint(RC) delivers a high-precision, high-stability clamping solution tailored for JAINNHER single-spindle internal grinding machines - breaking through previous technical constraints and enabling unprecedented machining accuracy.

From Challenge to Innovation

Workpieces

in internal grinding are often incredibly small and fragile, and uneven

clamping can result in deformation. Traditional chucks struggle with issues

like coolant and chip ingress, which deteriorate precision and shorten

lifespan. Driven by principles of precision positioning, robust clamping,

and workpiece protection,

AUTOGRIP developed this back-pull, end-stop solution through extensive research

and testing.

Advantages of the Solution

- High-Stability End-Face Positioning

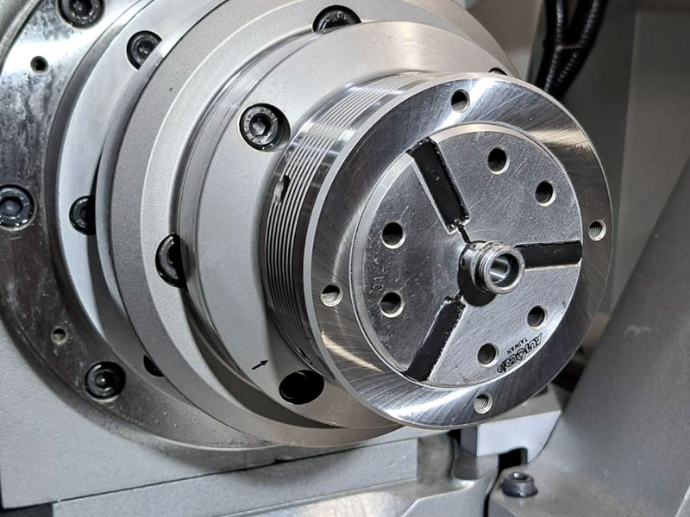

The back-pull end-stop mechanism, combined with a backgauge block, provides radial clamping and axial fine-tuning torque to accurately control the workpiece feed length—achieving positioning precision at the micron level. - Rubber Grip Collet Chuck Design

Featuring full-circumference uniform clamping via a rubber grip collet, this design minimizes deformation and damage to delicate workpieces. The interchangeable backgauge block and dust cover offer integrated chip-proof functionality. - Support for Ultra-Small Workpieces

Capable of clamping workpieces as thin as 1 mm, ensuring deformation-free handling - critical for sectors like medical and aerospace where precision is paramount. - Supports Center-Through Coolant and Airtight Testing

The RC rotary hydraulic cylinder features a center through-hole design and supports connection to single- or double-channel rotating joints—enabling coolant supply through the spindle and airtight pressure detection. - Stroke

Control and Automatic Locking

Equipped with a built-in check-valve self-locking mechanism, the RC cylinder can be paired with proximity switches or linear displacement sensors for stroke control, enabling accurate positioning and seamless automation.

Custom Value and Industry Applications

Engineered to integrate seamlessly with JAINNHER’s high-rigidity spindle and stable machine bed, this turnkey clamping system provides long-term stability, minimizes workpiece deformation, and supports automated production environments. Its versatility has proven invaluable in manufacturing fields requiring precision - such as aerospace, automotive, and medical equipment.

AUTOGRIP also offers tailored customization to meet specific operational

needs, reinforcing their reputation for responsiveness and engineering

excellence.