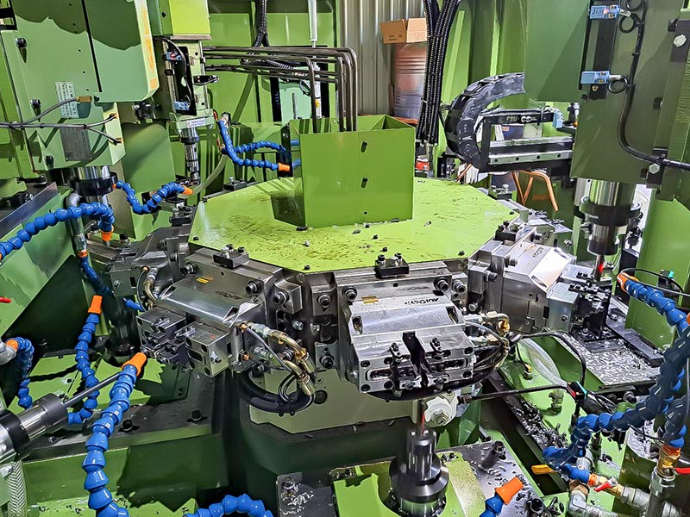

One-Stop Machining for Greater Efficiency

Traditional

machining often requires multiple setups and frequent workpiece repositioning,

which consume valuable time and reduce overall productivity. With disc indexing

technology, the VR-1214 system allows simultaneous drilling, milling, and

chamfering within a single machine, dramatically shortening cycle time and

reducing labor-intensive handling. This makes it an ideal solution for

companies aiming to streamline operations and boost throughput.

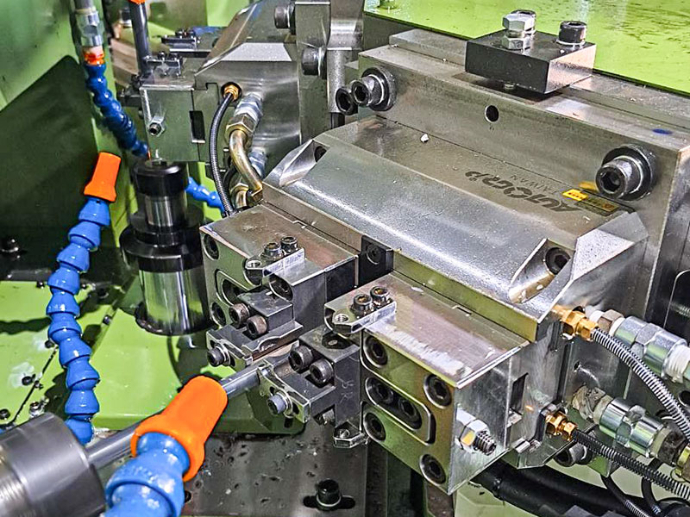

Flexible Drive Options and Easy Integration

The VR-1214 vise features a built-in hydraulic cylinder, offering flexibility with either pneumatic or hydraulic actuation to suit different production line requirements. In addition, the side air port interface makes installation quick and convenient, enabling seamless integration without major modifications to existing equipment.

Compact Design, Maximum Machining Space

Machine tool workspaces are often limited, making it vital to maximize available space. The VR-Series vise is engineered with a compact form factor, preserving valuable machining area and allowing greater freedom for tool movement. This design not only enhances machining efficiency but also improves overall shop-floor ergonomics.

Industry Applications

The VR-1214 system is an excellent fit for automotive components, aerospace structures, precision parts, and molds. By significantly reducing cycle time and ensuring consistent quality, it empowers manufacturers to stay competitive and embrace the shift toward automation and smart manufacturing.

The integration of the VR-Series Power Centering Vise with the 8-station rotary machining system combines efficiency, stability, and flexibility—offering the ultimate workholding solution for modern precision machining.

Related Products:

Power centering vise (VR type) Rotary Valves