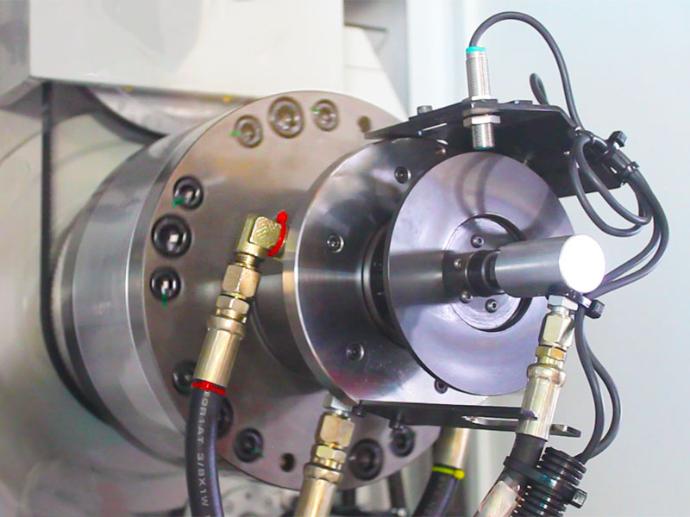

In today’s manufacturing environment, efficiency and precision go hand in hand. To meet customers’ needs for faster line changeovers and stable accuracy in heavy-duty applications, AUTOGRIP developed an integrated solution combining the Wedge-Hook Type 3-Jaw Power Chuck(3P-224) with the Hydraulic Cylinder with External Rotating Joint(RC-200S-M1), enabling multi-operation capability, minimizing downtime, and boosting overall productivity.

Dual-Process Machining Applications

- OP1: Internal Diameter Clamping

Shared jaw design eliminates fixture changes between OP1 and OP2, significantly reducing changeover time. - OP2: Spindle Center Air Blow

Precisely removes chips and debris from the workpiece surface to ensure consistent turning quality.

Advantages

- Change-free design — Greatly shortens machine stoppage time and reduces labor costs

- Airtight pressure detection — Single-channel rotating joint with proximity sensor enables real-time monitoring to prevent workpiece slippage

- High-rigidity construction — Withstands heavy cutting loads while maintaining machining accuracy

- Custom-engineered design — Tailored for various process requirements and adaptable to diverse applications

3P-224A11 Wedge-Hook Type 3-Jaw Power Chuck

- Hardened and precision-ground sliding surfaces with direct lubrication

- Customized spindle center air device to improve automation yield and efficiency

- Pre-drilled air ports on both the chuck body outer ring and end face for future expansion

RC-200S-M1 Hydraulic Cylinder with External Rotating Joint

- Solid-body design with internal channels for airtight detection and through-spindle coolant supply

- Built-in check valve for self-locking safety

- Compatible with proximity switches or linear displacement sensors for precise stroke control

This integrated solution has been widely applied to heavy-duty horizontal CNC lathes, helping manufacturers achieve higher stability, reduced setup time, and improved machining quality. AUTOGRIP remains committed to delivering innovative, reliable, and customer-focused workholding solutions.