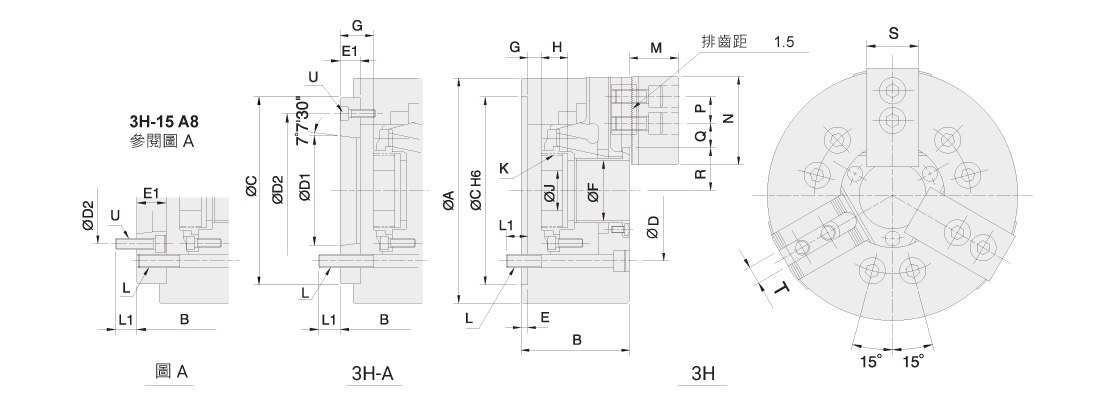

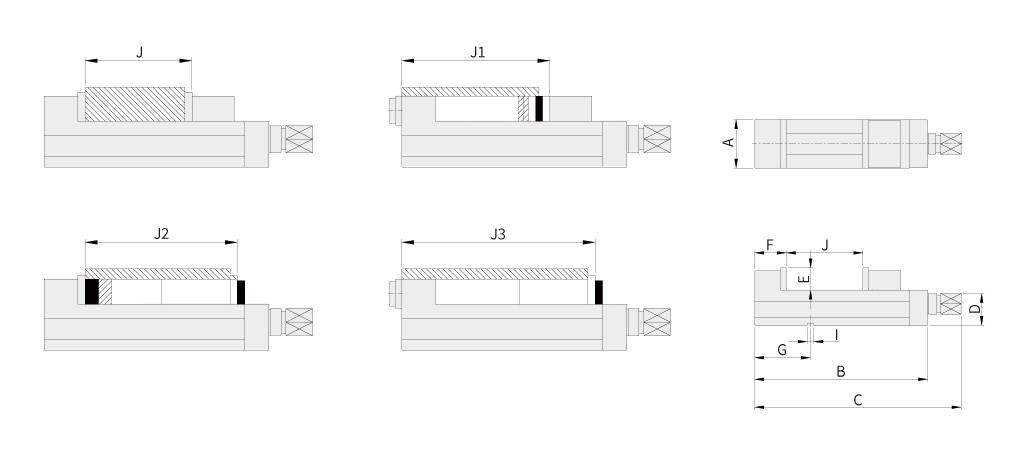

Dimensions

* Subject to technical changes.

| Model | A | B | C | D | E | F | G | I | J | J1 | J2 | J3 | Clamping Faoce (kgf) | Weight (kgs) |

| MVRH-100 | 101 | 380 | 480 | 85 | 48 | 80 | 125 | 16 | 135 | 200 | 240 | 330 | 4000 | 27 |

| MVRH-130 | 131 | 445 | 545 | 95 | 55 | 85 | 150 | 18 | 190 | 250 | 300 | 390 | 5000 | 40 |

| MVRH-160 | 161 | 535 | 635 | 105 | 58 | 100 | 165 | 18 | 250 | 330 | 370 | 480 | 5500 | 58 |

| MVRH-160L | 161 | 585 | 685 | 105 | 58 | 100 | 1465 | 18 | 300 | 380 | 420 | 530 | 5500 | 62 |

| MVRH-200 | 201 | 610 | 710 | 110 | 63 | 108 | 190 | 18 | 300 | 370 | 430 | 550 | 6900 | 81 |

J, J1, J2, and J3 indicate the maximum jaw opening.

Durable and precise chucks, specially designed for machining centers, enhancing performance and ensuring consistent quality and productivity.

production.

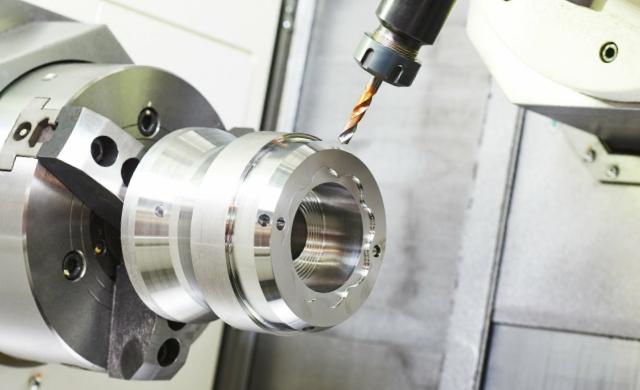

Turning Center

High-precision chucks, specifically designed for lathe centers, ensuring optimal performance and reliability in both small batch and large-scale production.

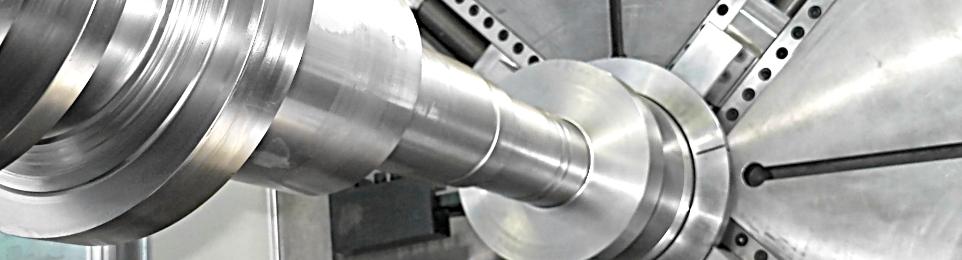

Special Purpose Machine

Customized chucks for special purpose machines, designed to achieve maximum efficiency and precision, with comprehensive ODM services.