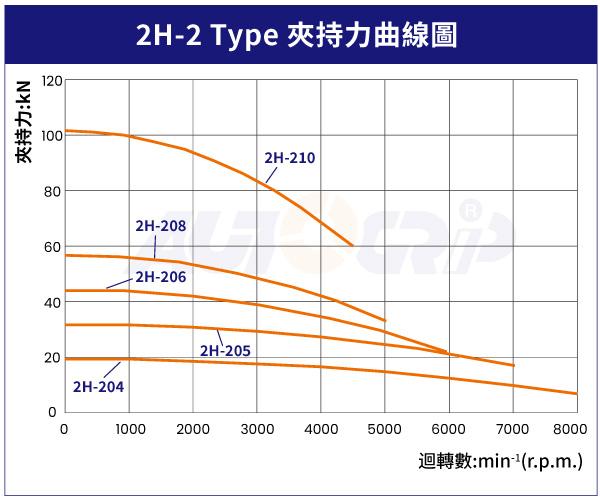

Specifications

| Model | - |

Plunger stroke (mm) | Jaw stroke (Dia.) (mm) | Chucking Dia. Max. (mm) | Chucking Dia. Min. (mm) | Max. D.B. pull kN (kgf) | Max. clamping force kN (kgf) | Max. speed min-1 (r.p.m.) | I kg‧m 2 | Weight (kg) | Weight (kg) | Matching cyl. | Max. pressure MPa (kgf/cm2) |

| 2H-204 |

A4 |

13 | 5.5 | 113 | 7 | 9.2 (940) | 19.4 (1980) | 8000 | 0.012 | 4.2 | 4.8 | TK-A528 | 1.3(13) |

| 2H-205 | A4 | 13 | 5.5 | 138 | 10 | 11.4 (1167) | 32 (3260) | 7000 | 0.02 | 6.8 | 7.6 | TK-A533 | 1.6(16) |

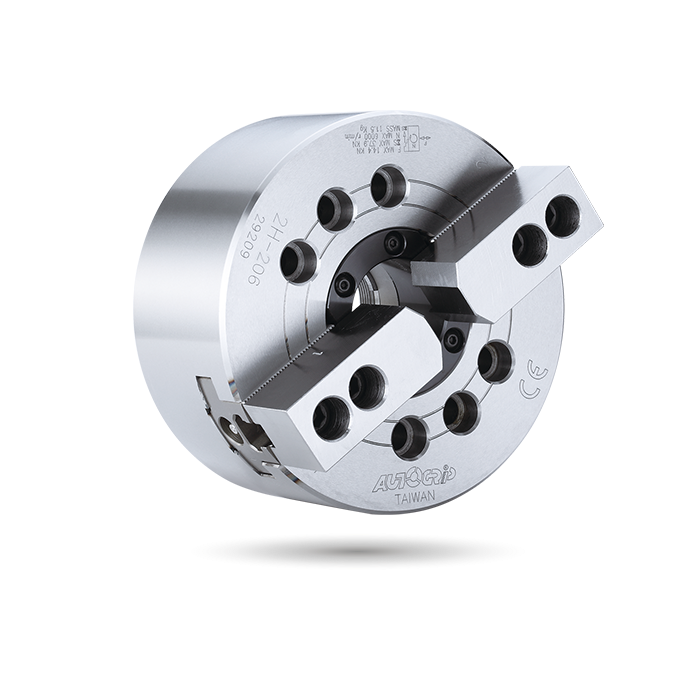

| 2H-206 | A5 | 14 | 6 | 170 | 13 | 15.5 (1580) | 44.4 (4530) | 6000 | 0.06 | 13.1 | 14.9 | TK-A646 | 1.6(16) |

| 2H-208 | A5 | 18 | 7.6 | 210 | 17 | 23.1 (2360) | 57.3 (5840) | 5000 | 0.17 | 21.3 | 24.2 | TK-A853 | 1.8(18) |

| 2H-208 | A6 | 18 | 7.6 | 210 | 17 | 23.1 (2360) | 57.3 (5840) | 5000 | 0.17 | 21.3 | 22.4 | TK-A853 | 1.8(18) |

| 2H-210 | A8 | 21 | 8.9 | 260 | 17 | 23.1 (2360) | 101.9 (10385) | 4500 | 0.31 | 33.5 | 36.2 | TK-A1075 |

2.2(22) |

* The 2H-2A's dimensions and specifications are shown in the orange data .

* The 2H-2 series are power chucks with extra large thru-hole design.

* The rotary cylinders are recommended based on power chucks that from are common used in the industry.

* If you find that you need different bore size or installation interface, please just contact us. We have many standard and customized rotary cylinders for option and meet your needs.

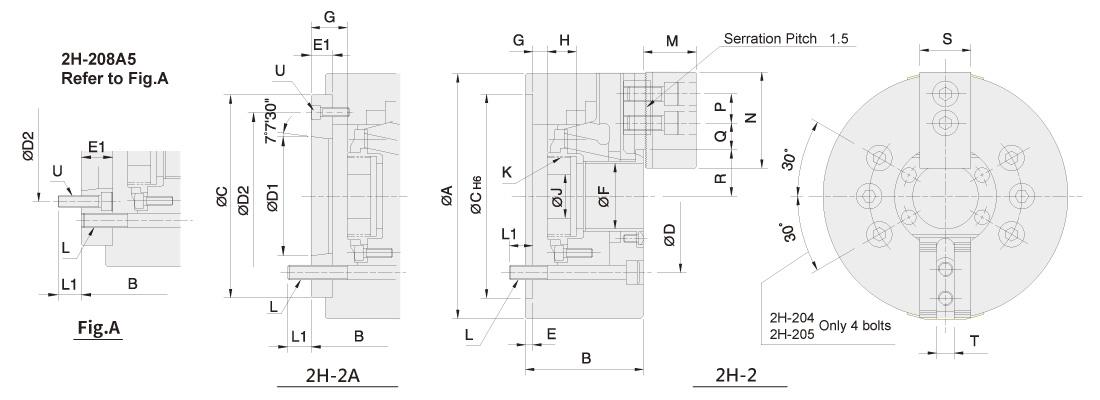

Dimensions

| Model |

- |

A | B | B | C | D | D1 | D2 | E | E1 | F | G max. | G max. | G min. | G min. | H | J | K max. | K Default | L | L1 | L1 | M | N | P | Q max. | Q min. | R max. | R min. | S | T | U |

| 2H-204 |

A4 |

113 | 59 | 83 | 85 | 70.6 | 65.31 | 82.6 | 4 | 28 | 32 | 3.5 | 31.5 | -9.5 | 18.5 | 17.5 | 12 | M38x1.5 | M32x1.5 | 4~M10 | 16 | 15 | 24 | 52 | 14 | 12.75 | 6.75 | 25 | 22.25 | 23 | 10 | 3~M10 |

| 2H-205 | A4 | 138 | 60 | 71 | 110 | 82.6 | 65.31 | 96 | 4 | 15 | 39 | 1 | 16 | -12 | 3 | 20 | 12 | M45x1.5 | M40x1.5 | 4~M10 | 15 | 15 | 31 | 62 | 14 | 20.25 | 6.75 | 29.5 | 26.75 | 25 | 10 | 3~M6 |

| 2H-206 | A5 | 170 | 81 | 91 | 140 | 104.8 | 82.56 | 116 | 5 | 15 | 53 | 13 | 28 | -1 | 14 | 17.5 | 20 | M60x2 | M55x2 | 6~M10 | 16 | 16 | 37 | 73 | 20 | 22.75 | 9.25 | 36 | 33 | 31 | 12 | 3~M6 |

| 2H-208 | A4 | 210 | 91 | 109 | 170 | 133.4 | 82.56 | 104.8 | 5 | 23 | 66 | 16.5 | 39.5 | -1.5 | 21.5 | 20 | 30 | M75x2 | M60x2 | 6~M12 | 17 | 18 | 38 | 95 | 25 | 23.7 | 10.2 | 45.7 | 41.9 | 35 | 14 | 6~M10 |

| 2H-208 |

A6 | 210 | 91 | 103 | 170 | 133.4 | 106.38 | 150 | 5 | 17 | 66 | 16.5 | 33.5 | -1.5 | 15.5 | 20 | 30 | M75x2 | M60x2 | 6~M12 | 17 | 15 | 38 | 95 | 25 | 23.7 | 10.2 | 45.7 | 41.9 | 35 | 14 | 3~M6 |

| 2H-210 |

A8 | 260 | 102 | 115 | 220 | 171.4 | 139.72 | 190 | 5 | 18 | 86 | 10.5 | 28.5 | -10.5 | 7.5 | 25 | 45 | M95x2 | M85x2 | 6~M16 | 20 | 22 | 43 | 110 | 30 | 32.2 | 12.7 | 56.5 | 56.5 | 40 | 16 | 3~M8 |

* The 2H-2A's dimensions and specifications are shown in the orange data .

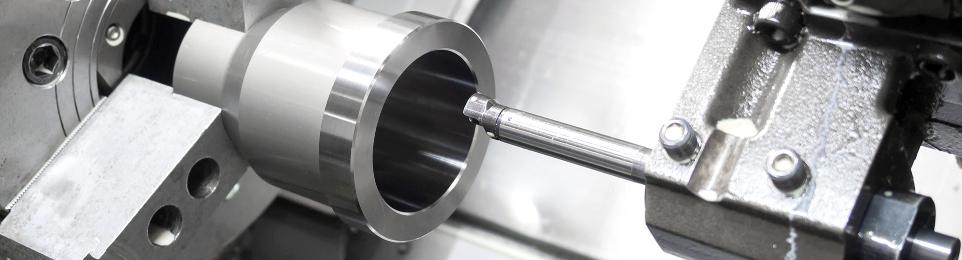

High precision chucks for turning centers, ensuring optimal performance and reliability in both small batch and large-scale production.

Durable and precise chucks for machining centers, enhancing performance and ensuring consistent quality and productivity.

Customized chucks for special purpose machines, tailored for maximum efficiency and precision, with comprehensive ODM services.