Specifications

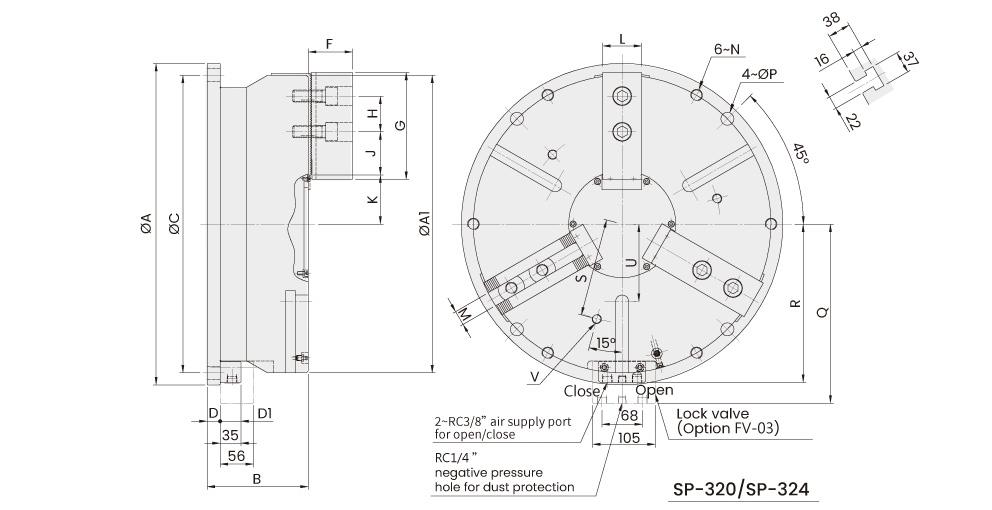

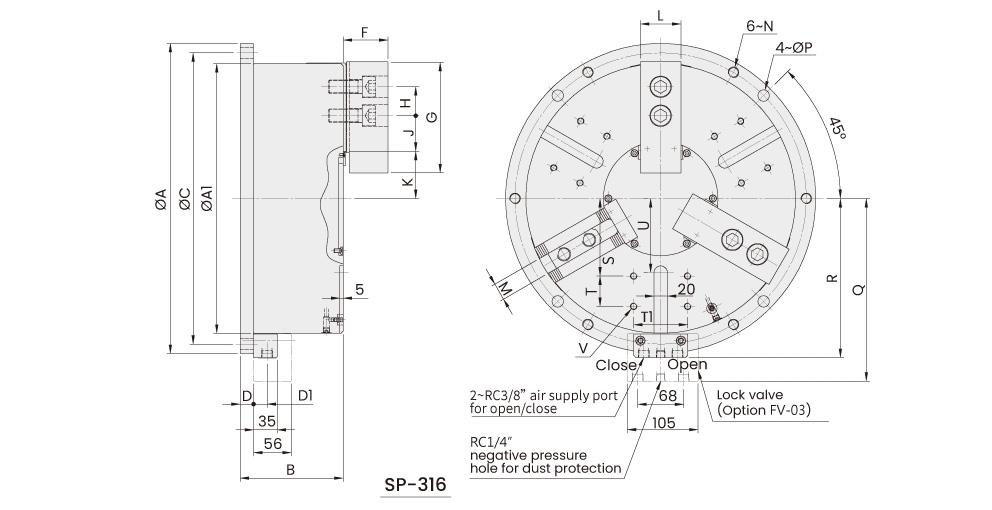

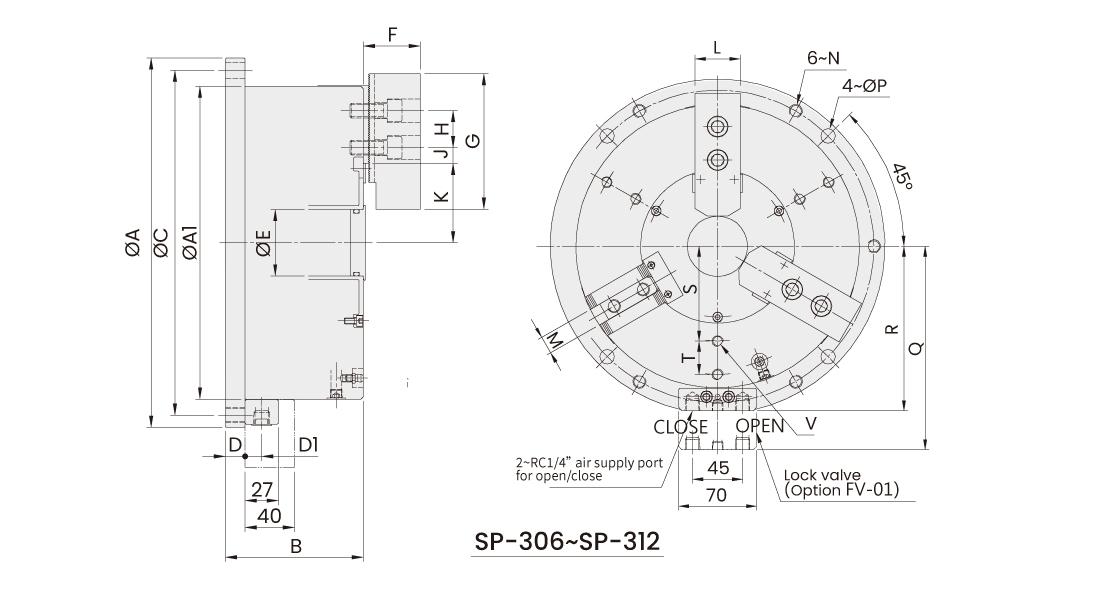

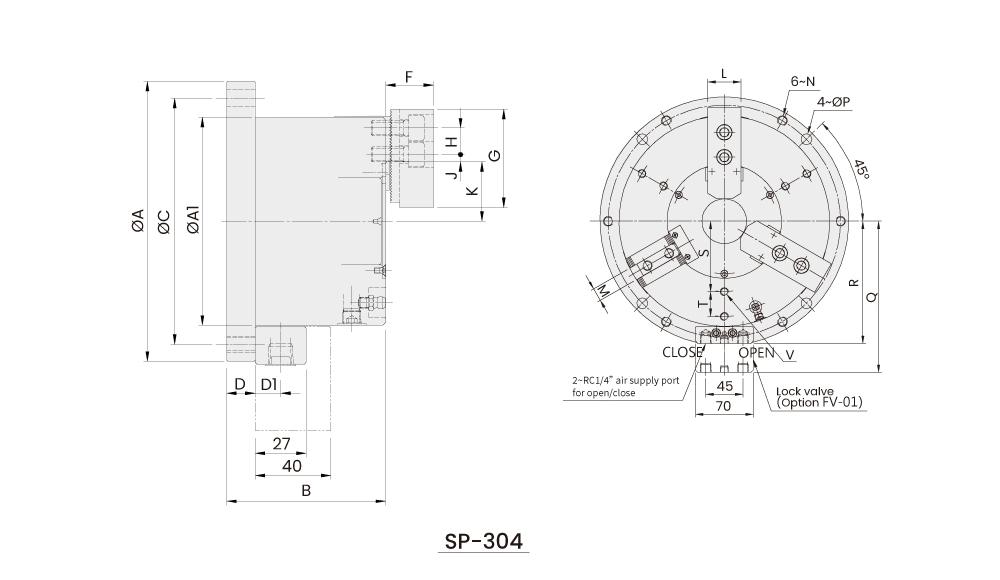

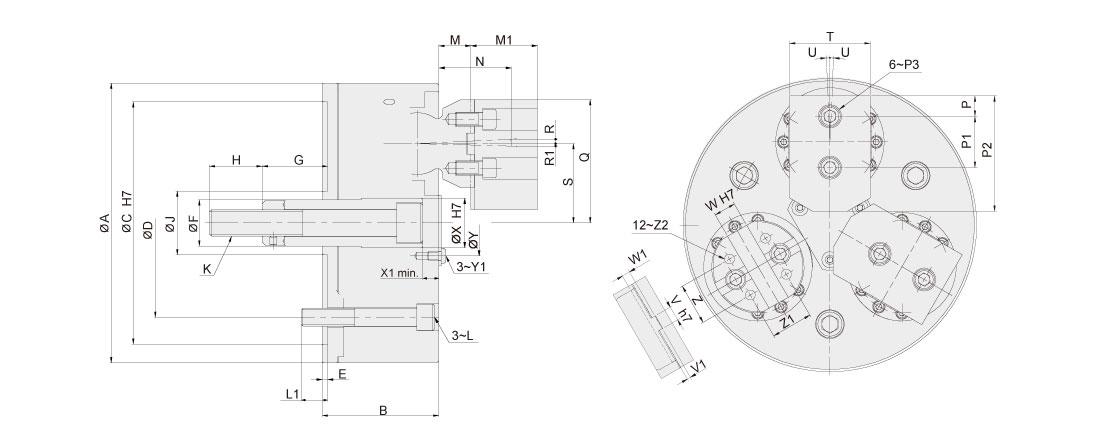

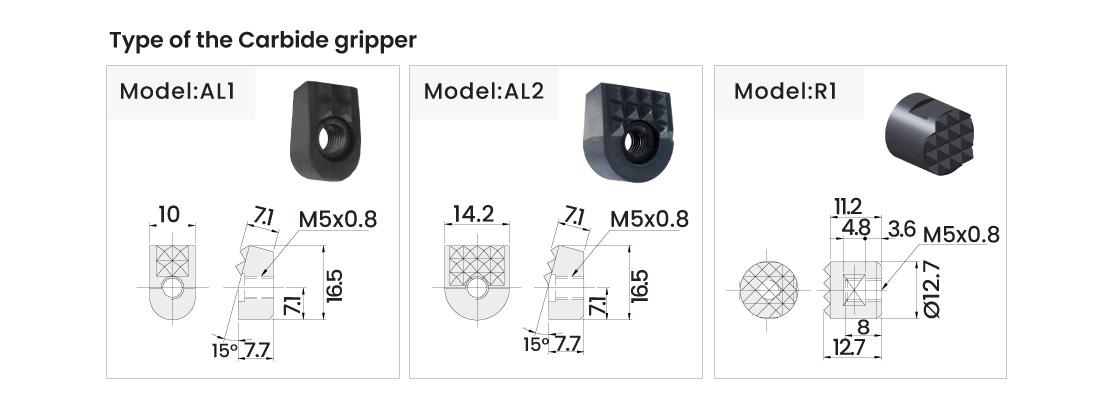

Dimensions

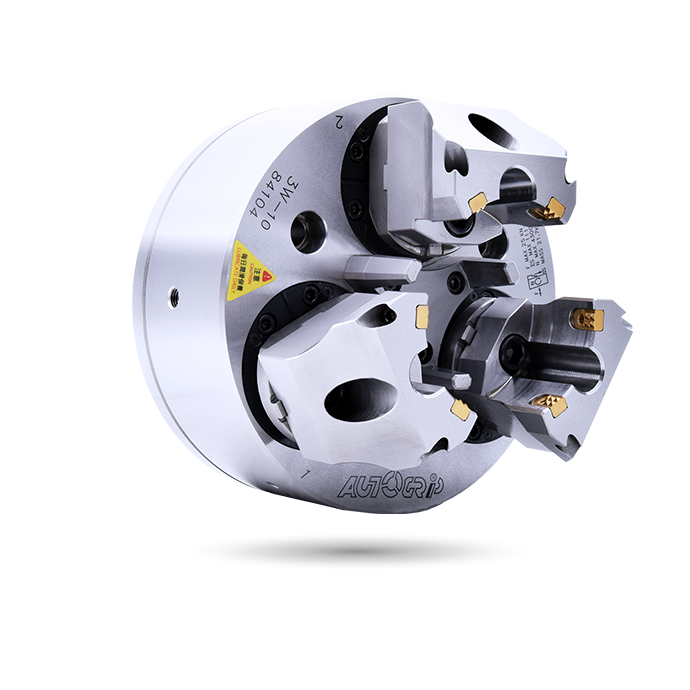

Applications

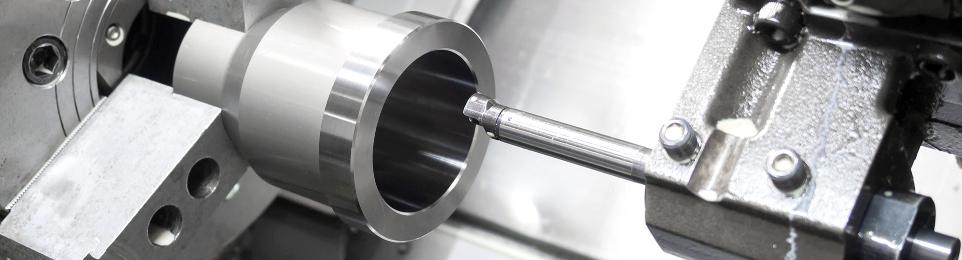

High precision chucks for turning centers, ensuring optimal performance and reliability in both small batch and large-scale production.

Durable and precise chucks for machining centers, enhancing performance and ensuring consistent quality and productivity.

Customized chucks for special purpose machines, tailored for maximum efficiency and precision, with comprehensive ODM services.