AUTOGRIP has always been customer-centric, focusing on developing diverse and innovative workholding solutions to help manufacturers worldwide achieve high-efficiency production.

We understand the challenges and pain points in valve machining, particularly its complex processes and high-precision requirements.

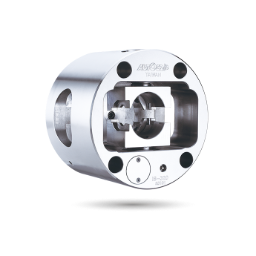

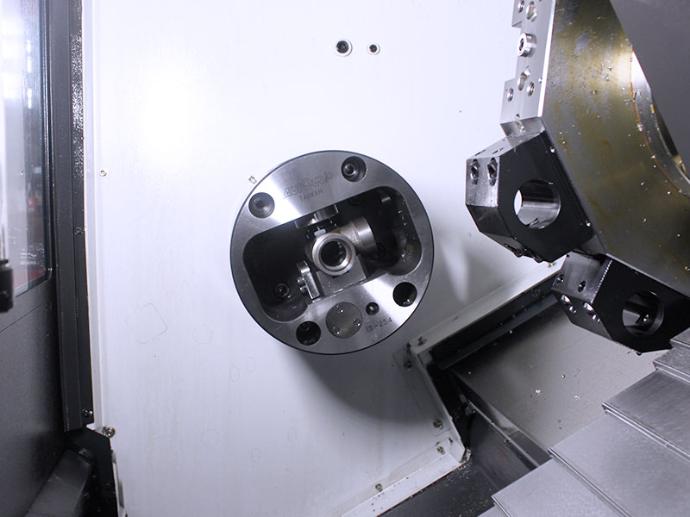

Leveraging the features

of the Power

Indexing Chuck (IS-254), we provide an effective solution for

valve machining, delivering a significant performance boost to our customers’

production lines.

High-Efficiency One-Setup Machining

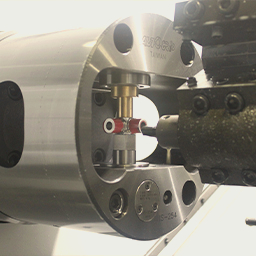

The power indexing Chuck(IS-type) function allows operators to quickly

complete multi-angle indexing while the spindle is running, enabling seamless

switching between multiple work positions. Surfaces, holes, and end faces of

valve bodies that previously required multiple setups can now be completed in a

single setup, greatly reducing machining cycle times.

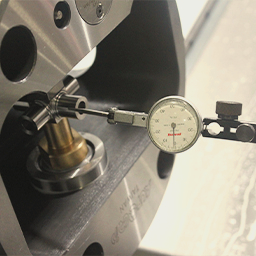

High Rigidity and Repeatability

All internal

components of the chuck undergo strict hardening and precision grinding,

ensuring excellent rigidity and wear resistance. Coupled with a precise

hydraulic indexing system and pressure detection mechanism, the

power indexing Chuck(IS-type)

can

securely hold irregular valve workpieces. Even under heavy cutting conditions,

it maintains stability and delivers reliable repeatability for consistent

quality in batch production.

Waterproof and Chip-Proof Design for Extended

Service Life

The chuck features a waterproof and chip-proof design to protect its

core components, ensuring long-term stable operation. This not only extends the

service life of the chuck but also reduces equipment maintenance costs.

| Real-World Application Results

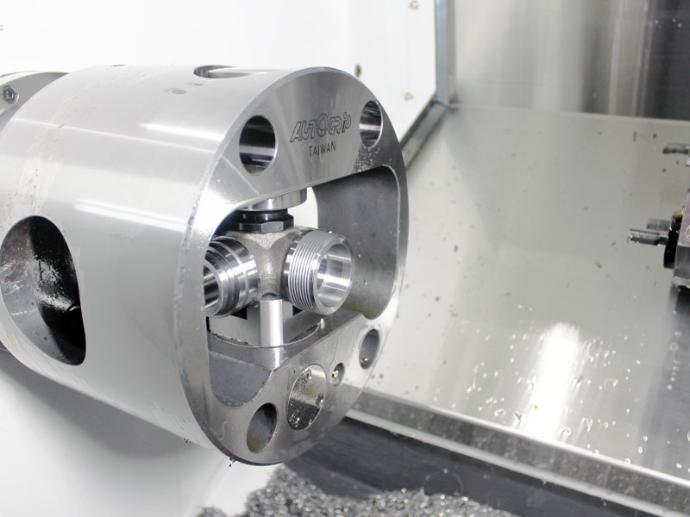

In this customer application, the IS-254 Power Indexing Chuck

successfully addressed machining challenges and redefined production efficiency

for valve products:

- Reduced Machining Time: Multiple operations completed in a single setup, significantly reducing changeover and downtime.

- Improved Quality: High rigidity and repeatability ensure precision for every operation, meeting the demands of high-end manufacturing.

- Lower Costs: Simplified workflow reduces human error, effectively lowering production costs and increasing yield.

This case demonstrates that even without full automation, the IS-254 Power Indexing Chuck can leverage its innovative indexing capability to help customers achieve high-efficiency, high-precision manufacturing.

AUTOGRIP will continue to focus on developing innovative workholding solutions to provide global manufacturers with more competitive advantages.

Related Products: Power Indexing Chuck(IS type)